Clean Water & Removable Insulation Blankets

When one thinks of clean drinking water, many things may come to mind – natural water sources, reservoirs, treatment facilities, to name a few. But you may be surprised to learn that removable insulation blankets have a role to play in bringing that fresh water to your table.

Admittedly, our blankets are not involved in the purification process directly. But a tour of a water treatment facility would likely reveal removable covers throughout.

Why are they there? Well, in our experience, there are a number of reasons why a water treatment facility may require removable insulation covers. Personnel protection, ambient heat reduction, and sound attenuation are examples where Firwin’s removable covers are playing an important ‘behind the scenes’ role.

In this 3 part series, we would like to present to our readership 3 different projects that we have done over the past few years for a local water treatment agency, highlighting the different approaches needed to meet the needs of each situation.

Part 1: Sound Attenuation – Where Vibrations may not be so ‘Good’

Although the Beach Boys might have been singing about ‘Good Vibrations’, such was not the case at the Water Treatment Plant where Firwin was called in to assist. The plant had two ‘Ozone Generators’, which are used to disinfect the water at the treatment plant. The noise being generated by these generators was quite loud, and a study was commissioned by the Ozone Generator manufacturer as to the options available to reduce the excess noise vibration.

The study recommended removable insulation blankets as a possible solution, and so Firwin was contacted.

The Recommendation

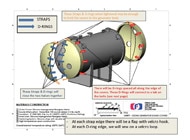

The study had identified that the primary culprit of the excess noise vibrations were the ends of the vessel, primarily the ozone end (the other end of the vessel is known as the ‘high voltage end’). The sides of the vessel were also identified as a source of noise vibration, but secondary to the ozone end.

The goal was to achieve a net reduction of 5 dBA, which would provide “a noticeable reduction in perceived loudness”. The study further recommended “a 2 inch thick layer of 4 lb/ft³ mineral wool insulation against the outer wall of the vessel, with an exterior layer of a minimum 1 lb/ft² air-impervious barium-loaded vinyl sheet.” If this proved to be insufficient, the side walls of the vessel would also be covered.

The Solution

The design team at Firwin proceeded to build the insulation cover for the ends of the Ozone Generator as per the specification of the study. It was a multi-layered blanket, with 2″ of mineral woll insulation and a 1lb/ft² sound sheet.

The design team at Firwin proceeded to build the insulation cover for the ends of the Ozone Generator as per the specification of the study. It was a multi-layered blanket, with 2″ of mineral woll insulation and a 1lb/ft² sound sheet.

Although the study also specified a silicone impregnated fiberglass outer cover, Firwin’s design engineer recommended that the outer cover be made with a PVC fabric instead, which ended up saving the client a significant amount of money. “Although the firm that did the study was correct in their assessment of what material makeup the sound blanket would need in order to achieve the desired results, going with a high temperature rated silicone outer cover was a bit of overkill”, said Firwin’s Alfredo Lopez, the design engineer who worked on this project. “As there were no high temperatures involved here, there was really no reason to use silicone, so we switched to the more economical PVC to save the client money. In addition, we used a fiberglass cloth inner liner, so as to allow the sound from the generator to be exposed to the pores of the mineral wool ” , added Alfredo.

Although the study also specified a silicone impregnated fiberglass outer cover, Firwin’s design engineer recommended that the outer cover be made with a PVC fabric instead, which ended up saving the client a significant amount of money. “Although the firm that did the study was correct in their assessment of what material makeup the sound blanket would need in order to achieve the desired results, going with a high temperature rated silicone outer cover was a bit of overkill”, said Firwin’s Alfredo Lopez, the design engineer who worked on this project. “As there were no high temperatures involved here, there was really no reason to use silicone, so we switched to the more economical PVC to save the client money. In addition, we used a fiberglass cloth inner liner, so as to allow the sound from the generator to be exposed to the pores of the mineral wool ” , added Alfredo.

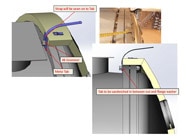

The final product consisted of cutouts and flaps for access points; fastening was with straps & double bar buckles. In order to ensure that the blanket would sit securely on the ends of the Ozone Generator, a unique method to fasten the blanket to the generator body was incorporated into the design, whereby the blankets would fasten via tags bolted on the generator body.

The final product consisted of cutouts and flaps for access points; fastening was with straps & double bar buckles. In order to ensure that the blanket would sit securely on the ends of the Ozone Generator, a unique method to fasten the blanket to the generator body was incorporated into the design, whereby the blankets would fasten via tags bolted on the generator body.

Conclusion

A follow up study done by the Generator manufacturer concluded that “by covering the Generator covered at both ends with a noise blanket, the noise was greatly reduced below the specification requirements of 80 dbm”.

For more information on our removable sound blankets, please contact us directly.

Other Articles: Altering Your Removable Insulation Covers – How to do it Right, Part I, Responsible Exhaust System Design, Firwinie is back!