Customized insulation covers for petrochemical, oil & gas, industrial process systems, and more.

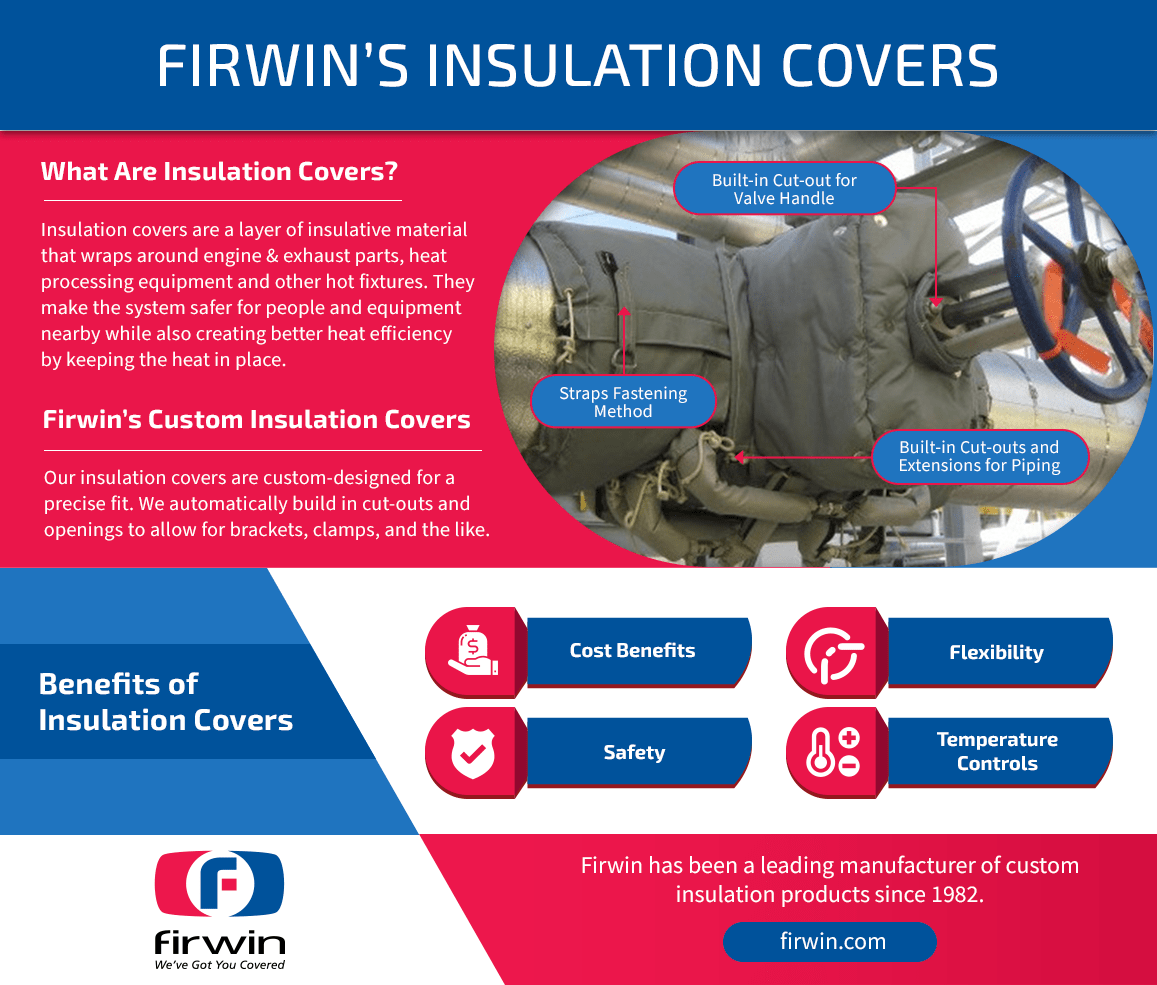

Insulation covers are a layer of insulative material that wraps around engine & exhaust parts, heat processing equipment and other hot fixtures. They make the system safer for people and equipment nearby while also creating better heat efficiency by keeping the heat in place.

Benefits of Insulation Covers

There are numerous advantages to be gained by installing removable insulation covers around exhaust components, and process and factory equipment. Here are some of the key benefits:

Cost Benefits

Uninsulated heat systems and heat processing equipment are inefficient because the heat can dissipate into the surrounding area and must constantly be replenished. Insulation covers keep the heat in place, so the systems require less energy to run. This results in significant cost savings Insulative covers also keep the equipment in consistently performing conditions, further saving money by maintaining quality control and resisting the risk of system malfunctions.

Flexibility

Removable insulation covers can be snapped, tied, or hooked into place. This makes them much easier to adjust, temporarily remove during inspections, and install than insulation tape, sleeves, or more permanent insulation solutions.

Safety

Because of the thermal control they provide, insulation covers help maintain the safe operation of heat and processing equipment. They also shield the surrounding environment from the equipment’s temperature. This keeps nearby workers safe from heat-related injuries and illness (especially in confined areas) and eliminates the risk that someone will brush up against unprotected pipes.

Sound Control

Insulation covers don’t just block temperature. They can also block sound. Industrial process equipment can generate ambient noise at levels that may distract workers, cause anxiety, contribute to long-term hearing loss, or prevent people from communicating or hearing safety alerts. With removable insulation equipment, facility managers can reduce the total amount of noise in a space.

Temperature Control

Insulation is essential for heat management in industrial facilities and can also assist with retaining heat generated by equipment to keep it from freezing up in cold or outdoor environments.

Insulation Cover Applications

An insulation cover provides heat control in systems where permanent insulation solutions are infeasible. For example, permanent insulation can’t be used around equipment and fixtures that need to be accessed, inspected, or modified regularly. Some of the most common commercial and industrial applications for insulation covers are:

- Valves. Valves may vary widely in size and shape, but fully customizable Firwin removable insulation covers wrap snugly around complex or unusually shaped equipment. While easy to remove for maintenance or valve access, thermal insulation covers still provide an ideal solution for protecting employees from burns and protecting valves from surrounding operating conditions.

- Flanges. The versatile nature of Firwin insulation covers makes them well-suited to covering flanges of all shapes and sizes. Insulation covers help to retain and control heat without posing external burn risks to employees.

- Vessels, manways, and tanks. Insulation covers for manways and vessels provide excellent heat retention, as well as protection against chemicals, heat, cold, and other external environmental conditions. Our covers provide years of durable use even in outdoor environments.

- Instrument panels. Instrument panels that must reliably operate in harsh environments often require an insulation solution to protect them from hazardous operating conditions. Our customizable insulation covers can protect panels while still providing easy access for maintenance or operational needs.

- Pumps and actuators. Pumps and actuators often operate in environments with extreme temperatures or other hazardous conditions. Insulation covers are easy to install and remove, offering reliable access to equipment without sacrificing protection from heat, cold, chemicals, and other harmful factors.

- Turbines. Firwin customizes removable insulation covers for all shapes and sizes of steam and gas turbines. We can make turbine blankets up to four inches thick, depending on safety needs.

- Engine & exhausts. Engines generate significant heat energy, but insulation can prevent that energy from dissipating into the surrounding environment and harming ancillary components. This allows well-designed systems to channel heat energy into a space where it can be used or safely dissipated instead of overheating the engine. Insulation can also shield nearby components from overheating and protect people near the heat output.