Removable insulation blankets or jackets are thermal insulating layers that, when attached to machinery and other mechanical components, can manage equipment temperature, optimize operational efficiency, and even enhance safety in the workplace. Unlike standard permanent or hard coat insulation, these blankets ensure that a covered machine or component is still accessible for maintenance. Learn more about the five key benefits of removable insulation blankets and how they compare to permanent varieties.

Removable insulation blankets or jackets are thermal insulating layers that, when attached to machinery and other mechanical components, can manage equipment temperature, optimize operational efficiency, and even enhance safety in the workplace. Unlike standard permanent or hard coat insulation, these blankets ensure that a covered machine or component is still accessible for maintenance. Learn more about the five key benefits of removable insulation blankets and how they compare to permanent varieties.

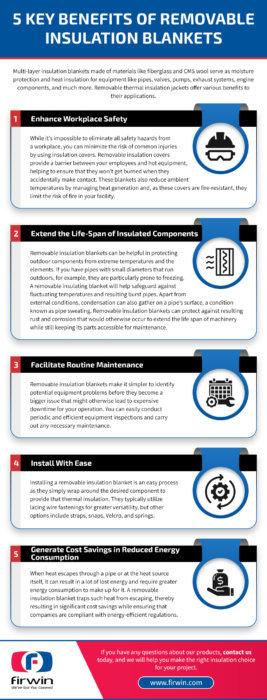

Key Benefits of Removable Insulation Blankets

Multi-layer insulation blankets of materials like fiberglass and CMS wool serve as moisture protection and heat insulation for equipment like pipes, valves, pumps, exhaust systems, engine components, and much more. Removable thermal insulation jackets offer various benefits to their applications.

Enhance Workplace Safety

While it’s impossible to eliminate all safety hazards from a workplace, you can minimize the risk of common injuries by using insulation covers. Removable insulation covers provide a barrier between your employees and hot equipment, helping to ensure that they won’t get burned when they accidentally make contact. These blankets also reduce ambient temperatures by managing heat generation and, as these covers are fire-resistant, they limit the risk of fire in your facility.

Extend the Life-Span of Insulated Components

Removable insulation blankets can be helpful in protecting outdoor components from extreme temperatures and the elements. If you have pipes with small diameters that run outdoors, for example, they are particularly prone to freezing. A removable insulating blanket will help safeguard against fluctuating temperatures and resulting burst pipes. Apart from external conditions, condensation can also gather on a pipe’s surface, a condition known as pipe sweating. Removable insulation blankets can protect against resulting rust and corrosion that would otherwise occur to extend the life span of machinery while still keeping its parts accessible for maintenance.

Facilitate Routine Maintenance

Removable insulation blankets make it simpler to identify potential equipment problems before they become a bigger issue that might otherwise lead to expensive downtime for your operation. You can easily conduct periodic and efficient equipment inspections and carry out any necessary maintenance.

Install With Ease

Installing a removable insulation blanket is an easy process as they simply wrap around the desired component to provide that thermal insulation. They typically utilize lacing wire fastenings for greater versatility, but other options include straps, snaps, Velcro, and springs.

Generate Cost Savings in Reduced Energy Consumption

When heat escapes through a pipe or at the heat source itself, it can result in a lot of lost energy and require greater energy consumption to make up for it. A removable insulation blanket traps such heat from escaping, thereby resulting in significant cost savings while ensuring that companies are compliant with energy-efficient regulations.

Removable Insulation Blanket vs. Permanent Insulation: Which Should You Use?

The right choice between removable and permanent insulation depends on your application. Your durability requirements, space constraints, a necessity for removability, and budget will ultimately be the deciding factors. When comparing the two, consider the following:

- Resistance to wear. Removable blankets may be tough, but they are typically not as impervious to damage as permanent insulation. Permanent insulation may be better suited to applications involving sharp objects to prevent tears.

- Space limitations. Permanent insulation such as Firwin’s Hard Coat insulation is applied directly to a component and conforms tightly to the part surface, making it ideal for applications with space constraints.

- Removability. For applications where periodic maintenance is beneficial, removable blankets are the obvious choice. They are even capable of reuse.

- Budget. With higher performance comes higher costs. High-performance permanent insulation such as Firwin’s Hard Coating is more expensive than the removable option for its durability.

- Lead times. Depending on the company, both permanent and removable insulation blankets typically have turn times of approximately two to three weeks. However, keep in mind that components for hard coat insulation need to be first shipped to the factory, where the insulation is applied, and then the insulated component is shipped back to the customer. This can result in additional delays and expenses.

Firwin: Your Removable Insulation Blanket Experts

Removable insulation blankets are critical additions for piping and machinery in various industrial processes, and Firwin Corporation is here to help. Whether you need a removable jacket or a permanent Firwin HC™ Hard Coat, you can count on us for high-performance products that meet your needs. We ensure high-quality blankets through our commitment to continuous process and production improvement, with our team embracing technological advancements to incorporate innovation into our product line.

Here at Firwin, we do our best to reply to all inquiries within a 24-hour period to best serve you with superior customer service. If you have any questions about our products, contact us today, and we will help you make the right insulation choice for your project.

Comments are closed