Insulation blankets are well-suited to outdoor applications such as exterior pipe insulation, but users still need to take some precautions to ensure that they function as intended.

The most obvious challenge faced by outdoor insulation blankets is the weather. Since insulated blankets aren’t impermeable, a heavy storm can cause water to seep in contributing to reduced insulation effectiveness, and possible corrosion of the pipes they’re designed to insulate. In extreme cold, water damaged blankets may leave the pipes they cover more susceptible to freezing and cracking.

To prevent such dire complications, companies need to educate themselves on proactive maintenance measures that can be taken to ensure that their outdoor insulation blankets are well-protected against the elements. With some understanding of the difficulties posed by outdoor pipe insulation, an informed user can ensure that adjustments to their blankets are done to prolong their working life and promote peak performance.

Common Materials

A standard insulation blanket includes an outer layer made of silicone impregnated fiberglass with UV-resistant coating, and a 1” thick middle layer of fiberglass material. Because of fiberglass’ chemical properties, a blanket made with it can withstand temperatures as low as -67◦F, ensuring that it can thrive in nearly any climate.

Other insulation blankets are made with ceramic fiber and Rockwool insulation rather than fiberglass. Though similarly durable, they offer slightly greater resistance to water than fiberglass, quickly recovering their designed insulation levels after water evaporates.

While all of these materials fare equally well under ideal conditions, the best material for your insulation system will largely depend on your surrounding climate.

Water Damage

As we noted above, water can creep into an insulation blanket. If it’s allowed to accumulate, moisture can cause corrosion on the inside and outside of your pipes, ruining your piping system. Constant exposure to precipitation or otherwise unforgiving conditions can also gradually weaken an insulation blanket until it ceases to function as intended.

As water enters through joints and jacket penetrations, it results in increased heat loss, which causes energy efficiency and (efficiency in general) to plummet. If the water remains present, the surface of the pipes may then experience ‘Corrosion Under Insulation’, while metal within the system may succumb to galvanic corrosion.

Solutions

While outdoor insulation blankets can fall prey to moisture-induced deterioration, there are an array of effective solutions available that minimize moisture penetration and reinforce pipes against harsh atmospheric conditions that minimize moisture penetration and reduce the likelihood of pipe corrosion.

At Firwin, we offer a number of tools and materials that counteract the effects of moisture in any industrial environment. All of our outdoor blankets, for example, can be designed with flaps that prevent water from entering a blanket at blanket joins. Our standard mesh inner liner can be replaced by material resistant to water in order to keep moisture away from the insulating materials.

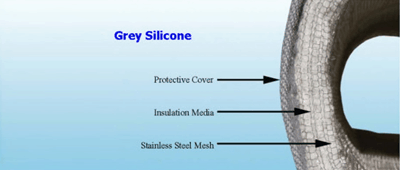

We also offer our customers heavy duty silicone outer cover for use in more severe outdoor applications, as well as larger size applications that demand greater strength and resistance. The heavy duty silicone cover provides superior resistance to abrasion, flexing, tears and punctures while preventing water, oil, and mold from accumulating.

Firwin’s outdoor insulation blankets are well-suited to a variety of industries from agriculture and forestry to oil & gas and power generation. Regardless of the specific application, we can work directly with you to understand your needs, educate you about your options, and devise the best insulation strategy for your business.

Whether you run a citrus facility in central Florida or an engine assembly plant in Michigan, Firwin can use its experience and expertise to develop an innovative and cost-effective solution to your insulation needs. Contact us today to see how we can assist you.