Firwin FAQ – How Much Clearance is Necessary for an Insulation Blanket

Insulation Blankets – Thicknesses and Clearances

As we have discussed in previous newsletter issues (see Fall / Winter 2014 ), it is important that there is enough room around any component being insulated to allow enough space not only for the insulation blanket, but also sufficient air space between the insulation blanket and any nearby surfaces. A lack of air space between the outer surface of an insulation blanket and another object can cause a heat build up on the blanket’s outer surface and possible deterioration of the blanket material.

With the typical blanket thickness of one inch, the question arises as to what to do with applications that require removable insulation, but have low clearances around all or part of the components to be covered?

“Insulating areas with low clearances can be an issue, but it often depends on the particulars of an application and what the client is wishing to achieve”, said Brett Herman, Firwin’s VP of Sales & Engineering. “For instance, sometimes just thinning out the insulation in areas of low clearance will still give the client sufficient insulation performance for the needs of his particular application. If, on the other hand, we are dealing with a relatively high temperature application, and the client has a particular temperature reduction goal that he wishes to achieve – this could be for personnel protection, or to ensure that nearby heat sensitive components are shielded from overheating – Whatever the reason, a lack of clearance means we are limited in the thickness of insulation that we can apply, which in turn can limit the amount of heat reduction that results”.

Solutions for Low Clearance Issues

So what solutions are available for situations where clearances restrictions would seem to limit the use of insulation blankets? “In situations where the client needs to achieve a certain temperature reduction, and there is insufficient room for the thickness that would be needed with standard fiberglass insulation, we have other solutions that we can offer to help the client achieve his goals”, said Brett.

“The first possibility we would look at is upgrading to a higher temperature insulation, such as MW1800 or FW2000+. These insulations have a higher temperature rating than our standard fiberglass FW1200, and sometimes when all that is needed is a small increase in insulation performance at a given thickness, these insulations will do the trick, with the price premium being relatively small “, notes Brett.

“If however, these do not suffice, the next step is to look at a high performance insulation such as Aerogel. It does carry a price premium, but it is one of the most effective insulators on the market, and will allow a client to achieve larger temperature reductions with a thin layer of insulation”.

High Performance Insulators

Insulation blankets are made up of 3 parts: The outer cover, also known as the `cold face`, the middle layer of insulation material, and the inner cover, or `hot face`. For most applications, the `standard` insulation blanket makeup of a silicone outer cover, 1 inch thick fiberglass, and a mesh inner liner, works fine. But certain applications demand alternative materials, be it because of very high temperatures, the environment where the insulation blankets will be operating, or in the case here, because of a combination of space constraints and desired insulation performance.

“Space constraints alone do not necessarily demand the use of an alternative insulator such as Aerogel”, said Brett. “It is possible that the customer`s needs can be met with a thin layer of fiberglass or superwool. An insulator like Aerogel is brought into the picture when the project needs insulation performance that typically could only be achieved with thicker insulation than the space allows.”

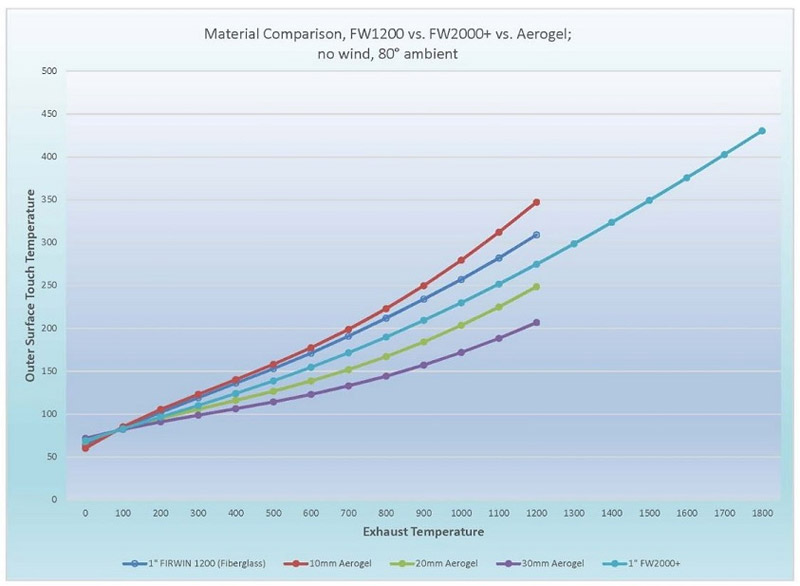

The chart below gives an indication of what kind of insulation effectiveness can be achieved even with a very thin layer of Aerogel insulation, compared to other insulations at standard 1″ thickness. As can be seen, even a thin 10 mm (approximately .4 inches) layer of Aerogel gives an insulation effectiveness near that of a 1″ thick fiberglass blanket.

Aerogel does carry with it a price premium, so it is only used in situations where the client must achieve a certain insulation performance even in low clearance areas. “For instance, let’s say the client’s application is of a high temperature, and the client needs the temperature of the outer blanket surface to be ‘touch safe’ (below 203°F). In a situation with no clearance issues, then the normal course would be to increase the insulation thickness to the level necessary to meet that target, say going from 1 inch to 2 inch thick insulation. But where clearance issues don’t allow that thickness, and the client absolutely needs to achieve their outer blanket temperature targets, we would recommend Aerogel”, said Brett.

For more information on how removable insulation blankets with Aerogel might be a solution for your particular application, please contact us directly.

Other Articles: Energy Audits and Insulation Blankets, Heat Tracing