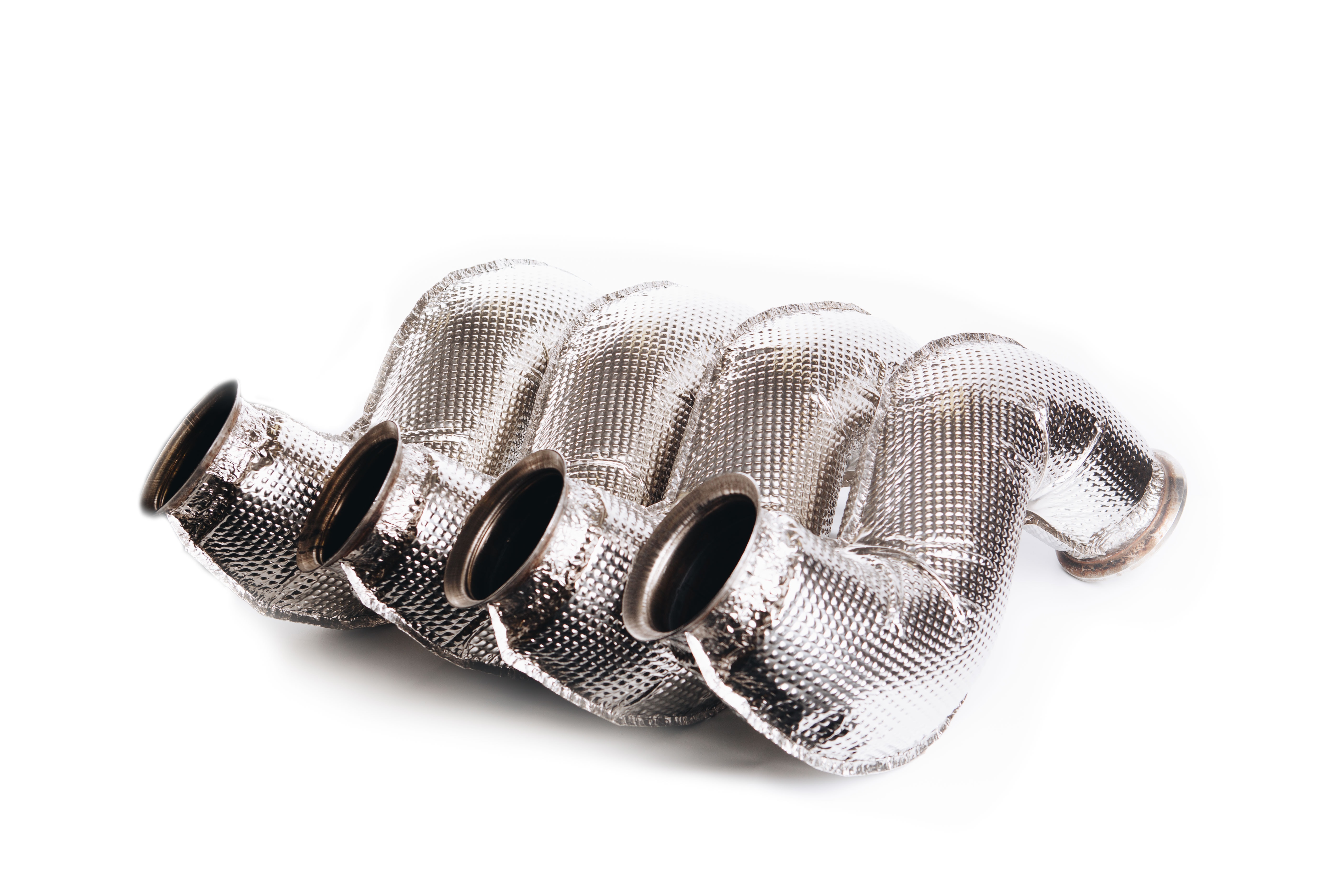

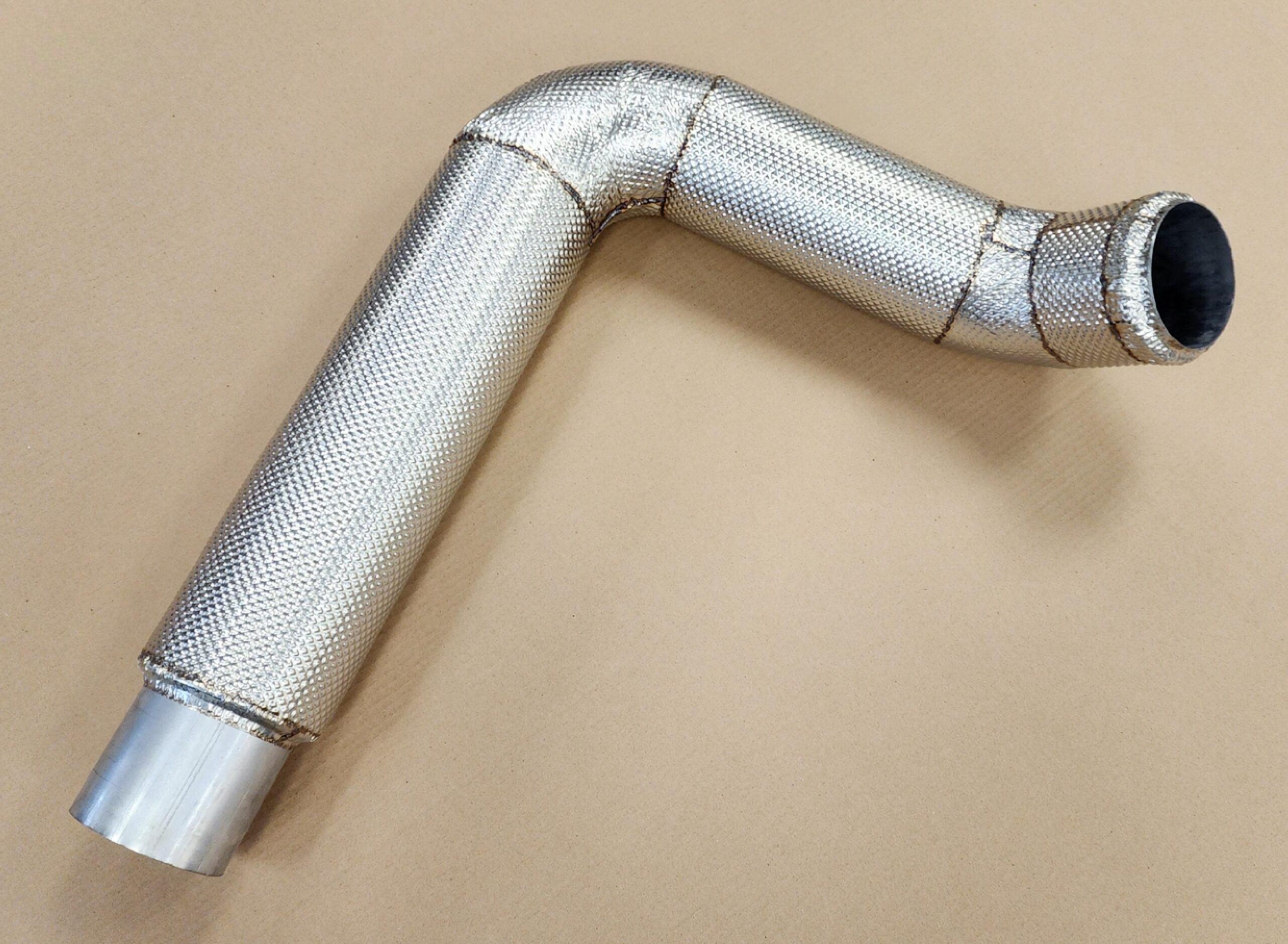

Firwin’s metal foil insulation, or MFI, is a specialty insulation product featuring an outer foil shield, designed for components in exhaust systems requiring a durable, aesthetically pleasing insulation cover that can contour to complex shapes.

Benefits of MFI

MFI is an extremely versatile insulation option with the following characteristics:

MFI is an extremely versatile insulation option with the following characteristics:

- Durability, with the ability to withstand extreme temperatures

- Resistance to damage and corrosion from exposure to fluids

- Flexibility, making it ideal to use on complex or unusual shapes

- Customizability in terms of material choice, thickness, shape, and other attributes

- Shiny, appealing appearance

Metal foil insulation is especially beneficial for use by original equipment manufacturers (OEMs) who need low- to medium-quantity orders of custom insulation.

Metal Foil Insulation Customization Options

MFI products can be customized to meet the shape, size, and regulatory requirements of a range of different projects or applications. Some of the customization options that Firwin provides include:

Insulation material

Overall thickness

Removable or non-removable options

Formed or non-formed options

Design elements

Our design and engineering team can work with your organization to develop the right-fit MFI products for your next project or specific applications.

Types of Foil Shields Used in Metal Foil Insulation

Firwin provides four types of foil shields for use in MFI products. To help you decide which is the best option for your application, consider this overview of each one’s pros and cons.

- Welded-on Formed Stainless Steel Heat Shields

- Welded-on Non-Formed Stainless Steel Heat Shields

- Removable Formed Stainless Steel Heat Shields

-

Removable Non-Formed Stainless Steel Heat Shields

Pros:

- Good level of seal to tube/part

- Good aesthetic

- Can be removed and replaced easily

- No tooling

- Lower cost compared to the formed type

Cons:

- The customer needs to install, a higher level of effort is required over the formed type

309 and 321 Stainless Steel Options

Choosing the right metal for foil insulation products is essential. Stainless steel is strong, resilient, and resistant to corrosion. At Firwin, we construct embossed heat shields from stainless steel 309 and stainless steel 321.

Both grades share similar excellent characteristics for corrosion resistance, heat dissipation, strength, durability, structural integrity, and versatility. However, 321 offers slightly better resistance to corrosion at high temperatures, and 309 has more mechanical strength at high temperatures. 309 is also slightly more resilient and resistant to pitting. Embossed 309 shields can be as thin as 0.002”, while 321 shields can be as thin as 0.005”.

Best Industries and Applications for Metal Foil Insulation

Firwin supplies high-quality MFI shielding for the following industries:

Highway and off-highway transportation

Marine

Military and defense

Mining

Some of the most common applications for MFI are in insulating industrial exhaust systems. Pipes, tubes, and elbow joints can release high levels of heat without effective insulation, so MFI shielding around these components ensures greater operational safety and efficiency.

Quality Exhaust Pipe Insulation From Firwin

Metal foil insulation can enclose industrial exhaust system parts to keep heat within the system, protect nearby personnel and equipment, and reduce energy loss. The production team at Firwin can typically complete MFI orders with a lead time of three to four weeks. Contact us today to learn more about our custom capabilities, request a quote to start your order, or if you’d like to learn more about the product, you can request more information here.

Featured Resources

Gain more insight into insulation blankets with three of our most popular eBooks.

Choosing the Right Insulation Blanket Supplier

Download

Tapes & Sleeves vs. Removable Covers

Download