Hard Coat vs. Removable Insulation Blankets – which one is right for my application?

Although Firwin is one of North America’s leading manufacturers of removable insulation blankets, we see ourselves as an insulation solution provider, offering our customers the most appropriate insulation solution that meets their needs. That is why we offer tapes and sleeves and is why we introduced our Firwin HCTM “Hard Coat” product last summer. As opposed to insulation blankets, which are designed to be removable and reusable, Firwin HCTM is an insulation coating that is affixed to the product. Both removable insulation blankets and Firwin HCTM have their advantages and disadvantages. What variables need to be considered in order to determine which insulation is right for a given application?

“There are a number of factors to consider,” said Bret Herman, Firwin’s vice president of engineering and customer service. “Does the customer require removable insulation? Are there space constraints? Is the application such that there is the potential of fluid seeping into the insulation material, thereby posing a fire hazard?. These are just some of the factors that need to be taken into account when deciding between Hard Coat and standard removable insulation blankets,” added Brett.

The chart below outlines the various advantages and disadvantages of Firwin HC vs. Removable Insulation Blankets. As always, it is best to let one of Firwin’s customer service representatives help you in choosing the best system for your particular application.

Firwin HCTM Hard Coat vs. Removable Insulation Blankets |

|

|

|

| Permanently applied to the component – cannot be removed | Blankets can be removed and reused – ideal for equipment that requires periodic maintenance |

| Solid outer surface – not prone to tearing, ideal for applications under rugged conditions | Standard removable insulation blankets have silicone impregnated outer surface – may tear or puncture under rugged conditions. |

|

The component must be disassembled and shipped to Firwin for HC coating to be applied |

Removable insulation blankets are designed remotely from measurements, drawings, and photos. The component remains with the customer, attached to the equipment. |

| Conforms tightly to part – ideal for limited space applications | Limited space applications can pose a challenge to blanket installation and proper fastening. |

| Completely encapsulates the part – preventing fluids from igniting on hot engine and exhaust parts | Blankets can act as a shield to prevent fluids for reaching engine and exhaust components, but some seepage under the blanket can occur. |

| No risk of fluid reaching insulation material and igniting | Can be designed with stainless steel inner liner to prevent fluids from seeping into the insulation material |

| Non-flammable | Fire retardant |

| Lead time of 3 weeks | Typical lead time of 2 to 3 weeks; can usually be expedited if necessary |

|

Higher cost (6 to 12 times) than standard removable insulation blankets, but longer life span. |

Cost can vary according to material make-up of blanket, but more economical than Hard Coat. Blanket life depends on application, and frequency of removable. |

Removable Insulation Blankets vs. Permanent Composite Insulation

Choices For Engine Powered Vehicles and Equipment

Choosing between removable thermal insulation blankets and Hard CoatTM permanent insulation depends on the application.

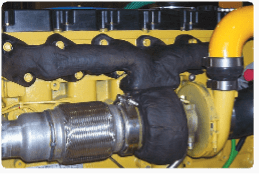

Insulating hot surfaces on engines and exhaust systems remains a key operating and safety issue for engine-powered vehicles and equipment. Among the benefits of applying thermal insulation covering to engine manifolds, turbochargers, and other hot exhaust components are:

- shielding hoses, wiring, and electronic components from malfunctioning due to excess heat

- protecting personnel from burns

- maintaining exhaust heat at level required for optimal catalyst performance

- sound attenuation

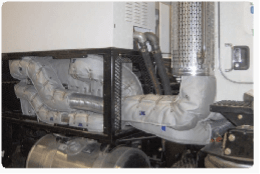

While removable thermal insulation blankets have typically been the insulation of choice, recent advances in rigid insulation have given equipment designers and packagers more variety as to what medium to use when insulating their engine and exhaust components.

Firwin Corp’s Hard CoatTM insulation is one such example of the new generation of rigid insulation. The product features a durable, lightweight exterior, and is typically applied to components such as exhaust manifolds, turbochargers, elbows, and exhaust piping. Unlike removable insulation blankets, which are wrapped around an engine or exhaust component and fastened with a fastening system (typically stainless steel lacing wire), Hard CoatTM insulation is a permanent insulation applied directly to the component being insulated. This results in the insulation material being completely enclosed and shielded from exterior elements. As such, the danger of equipment oil and fluid leaks that might otherwise seep into the insulation material and cause a potential fire hazard is eliminated.

Among the industries that have taken to Hard CoatTM type insulation over removable insulation blankets are marine, defense, and especially underground mining, where shielding the insulation material from leaked engine oil or hydraulic fluid is a top priority.

According to Firwin President Paul Herman, “For certain high-temperature applications where safeguarding for oil leaks is a priority, space is at a premium, and an insulation product is required, Hard CoatTM insulation is a definite option, and may be more economical in the long run.”

that there are a number of factors to take into consideration when deciding between Hard CoatTM insulation and removable insulation blankets. “Does the customer require removable insulation? Are there space constraints? Is the application such that there is the potential of fluid seeping into the insulation material, thereby posing a fire hazard?”

Each of the technologies has its own particular advantages and drawbacks. The rigid outer surface of Hard CoatTM insulation makes it less prone to tears or punctures than standard silicone-impregnated insulation blankets, and more resistant to damage from fluid leaks. It also makes Hard CoatTM insulation more durable than blankets. In addition, Hard CoatTM insulation is typically more compact than insulation blankets, as the insulation is formed directly on the component to be insulated. The disassembled, non-insulated part is shipped to Firwin, where the Hard CoatTM insulation is applied via a proprietary process. The insulated part is then shipped back to the customer. The resulting compactness can be critically important in engine compartments where space is often at a premium.

“While permanent insulation such as Firwin Hard CoatTM has its advantages, there are drawbacks as well”, notes Paul Herman. “It cannot be removed should a part require servicing. The coating must be applied at our factory. It is also more expensive up front than traditional insulation blankets.”

Removable insulation blankets do have significant advantages for a number of applications. They are designed to be easily installed, requiring no special tools or training for installation. Importantly, they can also be easily removed, a key benefit where equipment may require periodic maintenance and inspection. Unlike Hard CoatTM which requires parts to be shipped to a factory, removable insulation blankets are typically designed remotely using measurements, drawings, and digital photos. The resultant blanket design is saved as a pattern, which can be referenced at a later date should the same part need an insulation blanket. Firwin Corp maintains an extensive library of patterns covering a wide range of engines and exhaust system components. Thus redesign is minimized, and replacement sections can be easily manufactured should any part of the insulation blanket become damaged.

Although removable insulation blankets can be susceptible to absorption of leaked flammable fluids into the insulation material, careful design and material selection can minimize this issue – Firwin’s MineWrapTM blankets designed for underground mining are a case in point. Finally, insulation blankets typically offer greater sound absorption than Hard CoatTM materials, and also tend to be more vibration resistant.

The chart below outlines the various advantages and disadvantages of Hard CoatTM vs. removable insulation blankets. As with most technologies, the choice as to which material to use comes down to the specific application. Firwin in-house and field personnel are trained to assist clients in choosing the most suitable insulation system for their particular situation.

Comments are closed