Engines, exhausts, and even Industrial systems may routinely reach extreme temperatures, sometimes as high as 2000° F (1100° C). These temperatures can quickly become dangerous both to employees and equipment. Without proper insulative materials, heat can escape industrial systems, resulting in higher energy costs and usage. As such, retaining heat is an essential goal for protecting workers and maintaining efficiency.

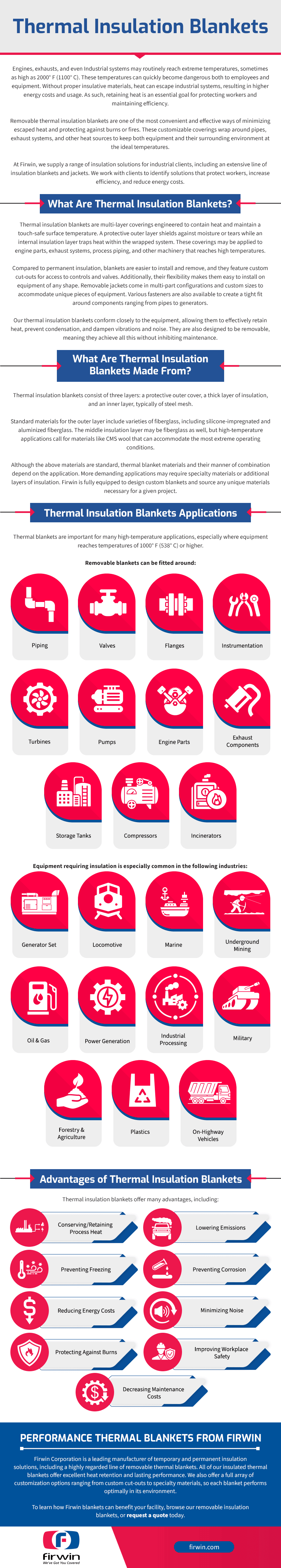

Removable thermal insulation blankets are one of the most convenient and effective ways of minimizing escaped heat and protecting against burns or fires. These customizable coverings wrap around pipes, exhaust systems, and other heat sources to keep both equipment and their surrounding environment at the ideal temperatures.

At Firwin, we supply a range of insulation solutions for industrial clients, including an extensive line of insulation blankets and jackets. We work with clients to identify solutions that protect workers, increase efficiency, and reduce energy costs.

What Are Thermal Insulation Blankets?

Thermal insulation blankets are multi-layer coverings engineered to contain heat and maintain a touch-safe surface temperature. A protective outer layer shields against moisture or tears while an internal insulation layer traps heat within the wrapped system. These coverings may be applied to engine parts, exhaust systems, process piping, and other machinery that reaches high temperatures.

Compared to permanent insulation, blankets are easier to install and remove, and they feature custom cut-outs for access to controls and valves. Additionally, their flexibility makes them easy to install on equipment of any shape. Removable jackets come in multi-part configurations and custom sizes to accommodate unique pieces of equipment. Various fasteners are also available to create a tight fit around components ranging from pipes to generators.

Our thermal insulation blankets conform closely to the equipment, allowing them to effectively retain heat, prevent condensation, and dampen vibrations and noise. They are also designed to be removable, meaning they achieve all this without inhibiting maintenance.

What Are Thermal Insulation Blankets Made From?

Thermal insulation blankets consist of three layers: a protective outer cover, a thick layer of insulation, and an inner layer, typically of steel mesh.

Standard materials for the outer layer include varieties of fiberglass, including silicone-impregnated and aluminized fiberglass. The middle insulation layer may be fiberglass as well, but high-temperature applications call for materials like CMS wool that can accommodate the most extreme operating conditions.

Although the above materials are standard, thermal blanket materials and their manner of combination depend on the application. More demanding applications may require specialty materials or additional layers of insulation. Firwin is fully equipped to design custom blankets and source any unique materials necessary for a given project.

Thermal Insulation Blankets Applications

Thermal blankets are important for many high-temperature applications, especially where equipment reaches temperatures of 1000° F (538° C) or higher. Removable blankets can be fitted around:

- Piping

- Valves

- Flanges

- Instrumentation

- Turbines

- Pumps

- Engine parts

- Exhaust components (i.e. silencers, catalysts, SCRs)

- Storage tanks

- Compressors

- Incinerators

Equipment requiring insulation is especially common in the following industries:

- Generator Set

- Locomotive

- Marine

- Underground Mining

- Oil & Gas

- Power Generation

- Industrial Processing

- Military

- Forestry & Agriculture

- Plastics

- On-Highway Vehicles

More generally, most applications with exhaust systems or exposed process piping can benefit from proper insulation. Firwin recognizes that each of these applications comes with unique constraints, so we offer a diverse set of standard and custom thermal blankets to meet varied industrial needs.

Advantages of Thermal Insulation Blankets

Thermal insulation blankets offer many advantages, including:

- Conserving/Retaining Process Heat. Thermal blankets prevent excess heat from escaping systems, helping them to reach and maintain their ideal operating temperature. This is especially important for emissions processing, which requires heat exhaust levels to stay above 800° F (427° F ).

- Lowering Emissions. Thermal insulation blankets help reduce emissions in two ways: by reducing energy consumption and by enabling emission processors to function efficiently.

- Preventing Freezing. Pipes that run outdoors may be susceptible to freezing, especially if they are small in diameter. In these settings, thermal insulation blankets prevent slowdowns or burst pipes caused by temperature fluctuations.

- Preventing Corrosion. Thermal insulation blankets can reduce or eliminate condensation, which has the effect of preventing corrosion. This benefit extends the working life of equipment and decreases maintenance costs.

- Reducing Energy Costs. Escaped heat is a significant source of energy loss. Preventing even a small degree of heat loss can lead to significant energy savings over time. Thermal insulation blankets do this by trapping heat that would otherwise be lost across the span of process piping, or by containing generated heat at its source.

- Minimizing Noise. As thick physical barriers, insulation blankets can be an effective part of your facility’s sound insulation strategy. Their vibration and noise dampening capabilities help maintain a safe level of background noise, protecting employees from potential hearing damage.

- Protecting Against Burns. One of the primary risks of high-temperature equipment is its potential to cause burns. Even incidental contact with hot equipment can seriously injure employees. With insulation blankets, the surface remains a safe temperature at all times, keeping employees protected.

- Improving Workplace Safety. In addition to mitigating the burn risk, heat management keeps the room at a comfortable temperature and reduces the possibility of fires. These factors make insulation blankets an easy way to reduce workplace accidents and ensure compliance with OSHA regulations.

- Decreasing Maintenance Costs. Thermal blankets keep systems at the ideal temperature, preventing harmful temperature fluctuations. Thermal blankets are easily removable, and they come equipped with flaps and cutouts to enable easy maintenance when required.

To experience all of these benefits, it’s important to select the right thermal blanket for your needs. As discussed, both the material and fit of the blanket influence the insulation’s efficiency. If the blanket is too loose or has an insufficient thermal resistance value, it will allow heat to escape, mitigating the potential advantages. That’s why it’s important to work with an experienced supplier when investing in any insulation solution.

Performance Thermal Blankets From Firwin

Firwin Corporation is a leading manufacturer of temporary and permanent insulation solutions, including a highly regarded line of removable thermal blankets. All of our insulated thermal blankets offer excellent heat retention and lasting performance. We also offer a full array of customization options ranging from custom cut-outs to specialty materials, so each blanket performs optimally in its environment.

To learn how Firwin blankets can benefit your facility, browse our removable insulation blankets, or request a quote today.