Maximum Blanket Operating Temperature

Removable Insulation Blankets are composed of a number of different material components: The actual insulation material, the inner and outer covers, and the fastening system. With each material component having its own unique temperature rating and characteristics, it can be somewhat unclear as to what is the maximum operating temperature of an insulation blanket.

One might think that as long as the temperature of the component being wrapped is below the temperature rating of the inner liner and insulation material, one is in the safe operating range for the blanket. But, as we will see, we must make sure that both the outer cover and the fastening system, whose temperature ratings are often lower than the other blanket components, are sufficiently insulated from the heat source so as not to exceed their maximum temperature rating.

Outer Cover:

As mentioned above, removable insulation blankets are typically composed of 3 layers (see diagram). The inner surface (hot face) that comes directly into contact with the hot component, and the insulation material that rests on it, both need to be able to withstand the maximum temperature (of the heat flow) of the component being wrapped. The outer protective cover (cold face) can typically be rated at a lower temperature, as it has the benefit of the insulation protecting it. The outer cover also has some sort of fastening system, typically stainless steel lacing wire (but other options are also prevalent).

As the outer cover typically has the lowest temperature rating of the 3 blanket layers (a standard blanket outer cover of silicone impregnated fiberglass is rated to 500°F), it is imperative that the insulation material be sufficiently effective to lower the temperature that reaches the outer cover to safe operating levels. High temperatures, or ineffective insulation, can result in outer cover temperatures going beyond the prescribed limit.

In the vast majority of cases, the temperature of the component being insulated is not sufficiently hot as to cause the outer surface of the insulation cover to go beyond its maximum operating temperature.

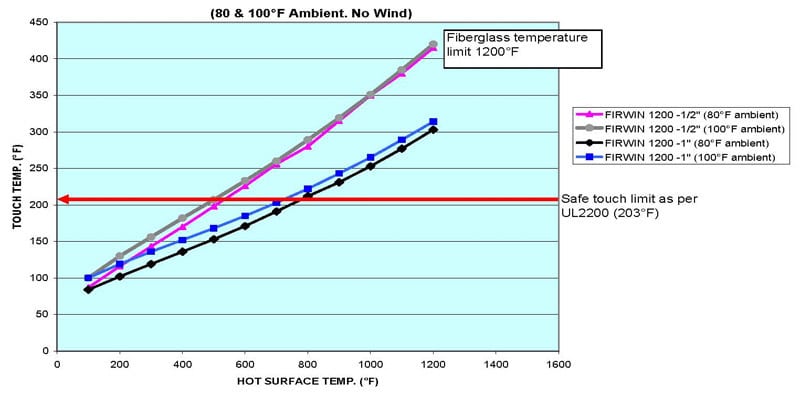

“For 1 inch thick insulation, or even ½” thick, you would need extreme high temperatures of beyond 2000°F for the outer blanket to reach a temperature beyond 500°F, which is the temperature limit for our stanadard silicone impregnated fiberglass cover”, said Brett Herman, Firwin’s Vice-President of Sales & Customer Service.

Factors Affecting Blanket Performance:

Aside from the heat flow temperature and insulation material, there are other factors that can affect the performance on an insulation blanket, and thus limit its overall temperature rating:

Fastening System:

Although the standard fastening system for Firwin removable insulation blankets is stainless steel rivets and lacing wire, which is rated to 1200°F, other fastening systems are available that may have a lower temperature rating than the outer cover. Velcro – type fastening, in particular, can start to break down at 200°F (there are higher temperature versions available). This would give an insulation blanket a lower temperature rating than it would otherwise have had with a more robust fastening system.

Air Clearance:

A lack of air space around the insulation blankets can cause a heat buildup around the outer surface of the blanket, potentially taking the surface temperature to beyond the temperature limit.

Contact of Other Items:

Should the outer surface of the blanket come into contact with other items, even if not hot, this could prevent heat from escaping the blanket and in turn cause an increase in temperature at the blanket outer surface.

Overlapping Blankets:

If the outer cover of an insulation blanket overlaps with another insulation blanket next to it, or the blanket is improperly installed so that the outer cover comes into contact with the hot insulation material of the blanket, this will raise the outer cover temperature.

Butting up against hot component:

Should the insulation blanket but up against a hot component, such as a flange, etc., this would obviously raise the outer cover temperature.

Gap between blankets:

Insulation blankets that are not installed properly, such that there is a gap between blanket sections, can experience higher than normal surface temperatures as the hot air between the blanket sections rises up.

“Because of these factors, we like to play it safe and give our removable insulation blankets a temperature rating somewhat lower than the maximum it can, in theory, handle”, notes Brett. “We also need to be able to account for potential spikes in engine temperatures, which could take the exhaust temperature beyond the assumed specification.”

A case in point: “We once had a client who was running his engine with our insulation blankets. When he turned off his engine, it also disabled the fan. All of a sudden there was hot stagnant air, which shot up the ambient temperature and consequently the surface temperature of the blankets. So we are careful to always leave a nice buffer when we rate the maximum temperature of our insulation blankets.”

High Temperature Outer Fabric:

Of course, Firwin blankets can be designed with high temperature outer fabrics, which would avoid most of these issues. Firwin HT is rated to 1300°F, while Silica can go as high as 1800°F. The drawback with these high temperature materials is that they cost more than the standard insulation blankets covers; and they are non-coated fabrics, so they lack some qualities, such as oil resistance, that the standard outer fabrics have (e.g. silicone impregnated fiberglass / Teflon coated fiberglass).

Of course, just changing the outer fabric alone won’t necessarily address all the issues of a high temperature application. “With really intense heat, insulation blankets need more detailed design, as environments can vary and many factors can come into play”, notes Brett.

For more information on how Firwin can help you with your high temperature application, please contact us directly.

Other Articles: Fire Blankets