Firwin Industry Series – Underground Mining

From scoops and scalers to pallet handlers and personnel carriers, underground mining relies on diesel-powered equipment to get the job done. Diesel power provides the mine with a rugged, reliable, and cost effective energy source; overall, diesel accounts for 72 percent of the energy used by the mining sector.* With developing economies such as China and India fueling demand and contributing to record high prices for aggregates, precious metals, and other natural resources, mining equipment manufacturers are experiencing an increasingly strong demand for diesel powered vehicles that can extract, load, and transport.

(* Diesel Service and Supply website, Industrial_Industry_Usage)

Diesel Powered Equipment in an Underground Environment: The Challenges

As can be imagined, underground mining poses a number of challenges when it comes to the safe and efficient use of diesel powered mining equipment:

•Exposed exhaust and engine components: Diesel exhaust can get extremely hot. With work in an underground mine often taking place within confined spaces, workers are at risk from severe burns from uncovered exhausts and engine components.

•Diesel particulate matter: Exhaust from diesel powered mining equipment must be properly filtered in order to protect personnel from noxious fumes. Fire Safety: Oil from a burst hydraulic hose, or from an engine leak, can start to smoke upon contacting exposed exhaust components.

•High ambient heat: The heat generated by diesel powered equipment can heat up an already sweltering underground environment. Furthermore, it can cause heat sensitive cables and sensors to malfunction.

Meeting the Challenges: How Insulation Blankets Can Help

Blanketing the exposed engine and exhaust components is an important step in meeting the challenges of operating diesel powered equipment. Once properly insulated, ambient heat is reduced, and workers are shielded from burns. A good ventilation system is of course essential in ensuring that hot air is removed and cooler air is brought in, and to remove noxious fumes from the mine.

As regards the latter, pollution control equipment, such as catalysts and particulate filters, are essential in removing much of the noxious material before it leaves the exhaust. Proper insulation can even help catalysts burn exhaust pollutants more effectively by maintaining an optimal high exhaust temperature as the exhaust travels along the piping and into the catalyst.

Standard Insulation Blankets: Why They Sometimes Fall Short

Standard insulation blankets have 2 features which can make them less than ideal for an underground mining environment:

The underside of a regular-issue insulation blanket is typically fiberglass material, which is non-combustible, held in place by wire mesh. While fine for most applications, in an underground mine, oil from a burst hydraulic hose line, or an engine leak, can seep underneath an insulation blanket and lodge in the insulation material. Separated from the hot component by only a wire mesh, this mixture of oil and insulation material can become a fire hazard, the last thing you want in a underground mine.

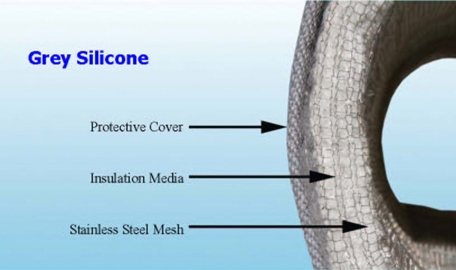

The second limitation of standard insulation blankets is the outer cover. Typically a silicone impregnated fiberglass, the outer cover is designed to be durable and withstand normal wear and tear for years. In an underground mine, however, the confined spaces and potential rock falls can lead to sharp objects coming into contact with the insulation blankets. Not designed to withstand this kind of treatment, regular insulation blankets can be prone to tearing or puncture.

MineWrap™ Insulation Blankets: Designed for the Underground Mine

To meet these concerns, Firwin’s R & D department designed a blanket with the specific needs of underground mining in mind. Known as MineWrap™ Mark II, this blanket features a stainless steel inner liner, which seals off the insulation material and prevents any oil from seeping in.

For those applications that require extra strength and rigidity to reinforce its outer cover, MineWrap™ comes in a Mark III version. The Mark III blanket features a reinforced stainless steel foil exterior, which in turn is covered with a stainless steel mesh. Joint safety seals can be added to further seal off any exposed exhaust between blanket sections.

With its added dimensions of increased fire safety and rugged exterior, MineWrap™ has become the insulation blanket of choice for a number of mines and equipment manufacturers.

Firwin Hard Coat: A Permanent Insulation Solution for Underground Mines

Some underground mines have determined that while they need their hot exhaust components insulated, they do not need to have the insulation be removable. These mines have opted for Firwin Corp’s Hard Coat™ insulation system . Hard Coat™ features a durable, lightweight exterior, and is typically applied to components such as exhaust manifolds, turbochargers, elbows, and exhaust piping. Unlike removable insulation blankets, which are wrapped around an engine or exhaust component and fastened with a fastening system (typically stainless steel lacing wire), Hard Coat™ insulation is a permanent insulation applied directly to the component being insulated. This results in the insulation material being completely enclosed and shielded from exterior elements. As such, the danger of equipment oil and fluid leaks that might otherwise seep into the insulation material and cause a potential fire hazard is eliminated.

Some underground mines have determined that while they need their hot exhaust components insulated, they do not need to have the insulation be removable. These mines have opted for Firwin Corp’s Hard Coat™ insulation system . Hard Coat™ features a durable, lightweight exterior, and is typically applied to components such as exhaust manifolds, turbochargers, elbows, and exhaust piping. Unlike removable insulation blankets, which are wrapped around an engine or exhaust component and fastened with a fastening system (typically stainless steel lacing wire), Hard Coat™ insulation is a permanent insulation applied directly to the component being insulated. This results in the insulation material being completely enclosed and shielded from exterior elements. As such, the danger of equipment oil and fluid leaks that might otherwise seep into the insulation material and cause a potential fire hazard is eliminated.

According to Firwin President Paul Herman, “For certain high-temperature applications where safeguarding for oil leaks is a priority, space is at a premium, and a removable insulation product is not required, Hard Coat™ insulation is a definite option, and may be more economical in the long run.”

“While permanent insulation such as Firwin Hard Coat™ has its advantages, for instance it compactness and durability, there are drawbacks as well”, notes Paul Herman. “It cannot be removed should a part require servicing. The coating must be applied at our factory. It is also more expensive up front than traditional insulation blankets.”

Conclusion:

While insulating exposed hot exhaust components are essential for underground mines, it is important to choose the correct insulation solution so that the insulation itself does not add any new safety concerns. MineWrap™ Removable Blankets and Hard Coat Composite Insulation have been designed to effectively insulate mining equipment exhaust components in a manner that encompasses the safety concerns of underground mines.

Comments are closed