High Temperature Thermal Insulation Product

Comments Off on High Temperature Thermal Insulation ProductMaking sure you select a material that can withstand the parameters of your application is a central requirement when choosing a high-temperature thermal insulation product. There are a variety of materials that can be used for insulation, and your selected material must be able to tolerate the specific demands of your equipment and operational environment.

High-Temperature Applications

When choosing an insulation solution for high-temperature environments, the tolerances of considered materials should be carefully examined to ensure safe operation and long service life.

Typical applications that experience high temperatures include:

- Furnaces and boilers

- Ovens and kilns

- Expansion joints

- Flanges

- Heat exchangers

- Compressors

- Turbines

- Chillers

- Incinerators

- Catalytic converters

- Engine & Exhaust Components

- Welding

- Dryers

- High-pressure steam piping

High-Temperature Insulation Materials

There is a range of insulation materials suitable for high-temperature usages, such as:

- Fiberglass

Fiberglass offers superb flexibility and dimensional stability for temperatures up to 1200º F. User-friendly with little odor or smoke, fiberglass will not corrode the metals it protects. One of the most common insulation materials, fiberglass is used in a wide array of everyday applications. - CMS Wool

Even though CMS wool is marginally more expensive than fiberglass, it is odorless and can withstand temperatures up to 2192º F. CMS wool is used in a broad range of common applications. - Super Wool

Super wool features a distinct low biopersistance and therefore requires fewer safety and health requirements when managing the material. Super wool exhibits low heat storage capacity and low thermal conductivity, as well as exceptional thermal shock resistance. Able to withstand a temperature range of 500º to 2000º F, common applications for super wool include domestic appliances, furnaces, kilns, laboratory ovens, boiler lining, reformers, fire protection, high-temperature gaskets, turbine insulations, expansion joints, and industrial equipment. - Ceramic fiber

This material is inorganic, smoke-free and features above-average insulation properties, low heat storage capacity, low thermal conductivity, and dependable thermal shock resistance. It is suggested for use in applications exceeding 2000º F. Typical applications of ceramic fiber include furnaces and kilns, high-temperature gaskets, expansion joints, boiler lining, laboratory ovens, reformers, and fire protection. - Polycrystalline Fiber

Made primarily of aluminum and silicon, polycrystalline fiber is created by using sol-gel technology. Double-needled fibers make polycrystalline fibers particularly strong and flexible. They can endure temperatures up to 2912º F and are tolerant of chemically destructive, oxidizing, or atmospherically reduced environments. Common applications include ceramic kilns and furnace linings.

Insulation materials come in a variety of options, and knowing which one to choose is crucial to effective and safe operation. Let us help select which option will work most effectively for your application. To learn more, please view our high-temperature insulation products or request additional product information.

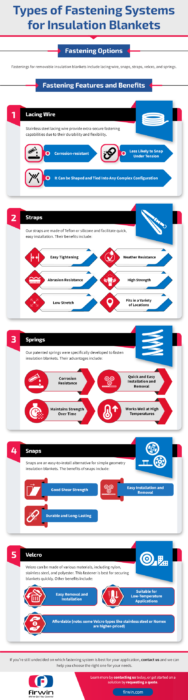

Types of Fastening Systems for Insulation Blankets

Comments Off on Types of Fastening Systems for Insulation Blankets Fastening systems are an important part of any insulation system. They secure the insulation, which is essential for preventing air leakage and maintaining thermal performance. Let’s look at the different fastening features and benefits.

Fastening systems are an important part of any insulation system. They secure the insulation, which is essential for preventing air leakage and maintaining thermal performance. Let’s look at the different fastening features and benefits.

Fastening Options

There are various ways to fasten removable insulation blankets, but the most common fastener is stainless steel lacing wire and rivets. This type of fastening is also often used for heavier blankets because it’s strong and durable. Other common fastening options include snaps, straps, Velcro, and springs. The best option will largely be influenced by your application type and budget, as each choice comes with its own set of benefits and disadvantages.

Fastening Features & Benefits

Rivets & Stainless Steel Lacing Wire

Rivets and stainless steel lacing wire provide extra-secure fastening capabilities due to their durability and flexibility. The material is corrosion-resistant and less likely to snap under tension, so it can be shaped and tied into any complex configuration.

Straps

Our straps are made of Teflon or silicone and facilitate quick, easy installation. Their benefits include:

- Easy tightening

- Weather resistance

- Abrasion resistance

- High strength

- Low stretch

- Fits in a variety of locations

Springs

Our patented springs were specifically developed to fasten insulation blankets. Their advantages include:

- Corrosion resistance

- Quick and easy installation and removal

- Maintains strength over time

- Works well at high temperatures

You can browse and purchase springs in our accessories store.

Snaps

Snaps are an easy-to-install alternative for simple geometry insulation blankets. They may not be the best solution for blankets with complicated geometries. The benefits of snaps include:

- Good shear strength

- Easy installation and removal

- Durable and long-lasting

Velcro

Velcro can be made of various materials, including nylon, stainless steel, and polyester. The best type of Velcro depends on the application. This fastener is best for securing blankets quickly. Other benefits include:

- Easy removal and installation

- Suitable for low-temperature applications

- Affordable (note: some Velcro types like stainless steel or Nomex are higher-priced)

Working With Firwin

Working with Firwin is more than just purchasing fastening systems for insulation blankets. We take the time to get to know our customers and their specific needs so that we arrive at the best-individualized solutions. We also build supportive professional relationships with our customers, so they can always count on us for sound advice. Whether you’re looking for a one-time purchase or a long-term solution, Firwin is your trusted partner for all insulation needs.

If you’re still undecided on which fastening system is best for your application, contact us and we can help you choose the right one for your needs.