Heat Trace Insulation in Oil and Gas Applications

Comments Off on Heat Trace Insulation in Oil and Gas ApplicationsHeat tracing—sometimes also called trace heating—is a system in which a heating element is run along the length of a pipe in order to prevent its contents from freezing. The heating element and pipe are often wrapped in thermal insulation to prevent heat loss and allow the heat tracing to operate more efficiently.

Even in locations where there is no risk of pipes freezing, some applications require that liquid in pipes be heated to a certain temperature. Heat tracing can be used to keep temperatures steady all along a system of pipes.

Importance in Oil/Gas Applications

Importance in Oil/Gas Applications

Heat tracing is a valuable tool in the petroleum industry. The equipment used to produce, process, and store oil needs to be kept at certain temperatures for peak performance, and so requires a heating solution to maintain optimal thermal levels. Additionally, when oil and natural gas are first being extracted from the ground, high temperatures are used to bring them to the surface.

Oil and gas refineries exist in nearly all localities and climates, so the equipment used for refining and distributing oil and gas products needs to be winterized at many facilities. There are other uses of heat tracing in the oil and gas industry as well, such as during exploration and throughout many stages of production.

Heat tracing is used heavily during the processing of gas, heavy oils, synfuels, and petrochemicals. This method keeps the refinement process running smoothly, and it is often used in storage terminals to control the temperature of the product.

Importance of Insulation on a Heat Trace

Insulation is also a key component of temperature control in oil and gas applications. In addition to maintaining equipment temperatures, insulation helps to:

- Reduce thermal loss

- Increase efficiency

- Improve process by temperature regulation

Key Examples of Product Applications from Firwin

Firwin provides a range of products that assist in temperature regulation of oil and gas pipelines. This includes:

- Valve Covers

Upstream equipment is often exposed to harsh conditions, especially extreme heat, cold, and chemicals. Our valve covers will keep your equipment sealed and secure.

- Flanges

To keep equipment at the right temperature and reduce heating and/or cooling costs, our ThermoWrap removable insulation blankets are custom designed to cover flanges of all shapes and sizes. All of our blankets come with highly secure fastening systems and are made of durable materials that can be used for years.

- Vessels/Manways

Safety is a key concern in any operation. Hot piping causes severe burns when exposed to skin, so it is vital that the outer cover temperatures be kept under control. Our vessel and manway covers help protect your employees.

- Instrumental Panels

Our instrumental panel covers provide excellent heat retention. Our removable blankets reduce waste and save money when compared to hard insulation removal and reapplication.

The products that we provide are designed to wrap and protect even the most complicated upstream equipment. Our experienced staff is highly in tune with the needs of the oil and gas industry and we’ve designed our products with those needs in mind.

Temperature control is a vital for oil and gas applications and Firwin is here to provide the products you need. View our line of insulation products for the oil and gas industry here.

Fasteners 101

Comments Off on Fasteners 101Firwin’s removable insulation blankets are generally fastened with stainless steel lacing wire, which we supply with most of our insulation orders. Occasionally, a customer requires an alternate fastening system. Sometimes, the customer’s application may require quick installation or frequent installation and removal of the insulation blankets.

To suit the needs of these customers, we also carry several types of fasteners. Our versatile range of insulation blankets can also be fastened with straps, snaps, springs, and Velcro. These options provide alternative fastening systems and more accessible ways of opening and closing insulation blankets.

Every fastening method has benefits and idiosyncrasies, making it is important to consider which one is right for your application. While choosing a fastener type for your insulation blanket, you should ask yourself the following questions.

- How often will the insulation blanket be accessed?

- Are there any environmental factors, such as temperature, potential water exposure, or corrosive elements, that need to be accounted for?

- What will the installation process look like?

- How much give do you require from your insulation blankets?

- Is this a self-install or will you use a professional contractor?

With answers to those questions, you can go about choosing the fastener that is right for your specific application.

Applications and Benefits of Each Fastener Type

As outlined below, each fastener type is suited for specific applications:

Stainless Steel Lacing Wire

Our most common insulation blanket fastener is stainless steel lacing wire. Stainless steel lacing wire provides an extra secure fit and durability.

Our most common insulation blanket fastener is stainless steel lacing wire. Stainless steel lacing wire provides an extra secure fit and durability.

Benefits provided by stainless steel lacing wire include:

- It can be bent or tied into any configuration necessary.

- Stainless steel is highly corrosion resistant.

- It is highly durable, and so you will not need to maintain or repair it.

Straps

Our silicone or Teflon straps can be used to fasten insulation blankets for a speedy installation. The benefits of straps include:

- Can be pulled taught for snug fit

- Straps are strong, weather-resistant, non-abrasive, and low-stretch

- Straps can be fitted into a variety of locations.

- Easier and more intuitive than lacing wire

Springs

Firwin created our own proprietary spring system for attaching insulation blankets. Unimpressed with other spring fastener solutions, we worked with a local manufacturer to develop a spring fastener that was simple to use with a long service life. Some of the benefits of springs include:

Firwin created our own proprietary spring system for attaching insulation blankets. Unimpressed with other spring fastener solutions, we worked with a local manufacturer to develop a spring fastener that was simple to use with a long service life. Some of the benefits of springs include:

- Springs are corrosion resistant, making them ideal for applications with corrosive environmental factors.

- They can be taken on and off easily for temporary applications or uses that require frequent removal and reinstallation.

- Springs maintain their integrity over time; they do not degrade.

- Springs can operate at high temperatures.

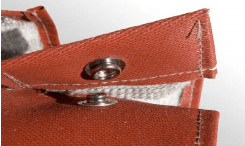

Snaps

We also offer snap closures to our insulation blankets, a cost-effective alternative. The benefits of snaps include:

We also offer snap closures to our insulation blankets, a cost-effective alternative. The benefits of snaps include:

- Excellent shear strength.

- Can be released quickly and easily when pulled at from an angle, making them great for quick-removal applications.

Snaps may not be an appropriate fastening solution for blanket setups that have complex geometries, or in applications that require give when fastening the blankets.

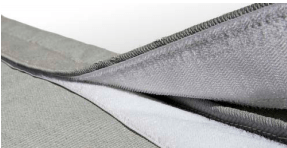

Velcro

Velcro offers an ideal solution for fastening blankets quickly and easily. The applications vary widely for Velcro, as it can be used on its own or as a supporting fastener in conjunction with other fasteners.

Velcro offers an ideal solution for fastening blankets quickly and easily. The applications vary widely for Velcro, as it can be used on its own or as a supporting fastener in conjunction with other fasteners.

The benefits of Velcro as a fastener for insulation blankets include:

- Easy installation and removal

- Good for low temperature applications

- Affordable (though certain Velcro types such as Nomex or stainless steel come at a premium)

Fasteners from Firwin

There are many different fastening methods available; the most appropriate method for a given application depends on a number of variables – cost, temperature, frequency of removal, speed of installation, and others. At Firwin, we work together with our customers to arrive at the best fastening method for their particular situation.

To learn more about the types of fasteners that Firwin offers, or with questions about fasteners for your specific application, please contact us today.