All About Elbows – What Measurements are required ?

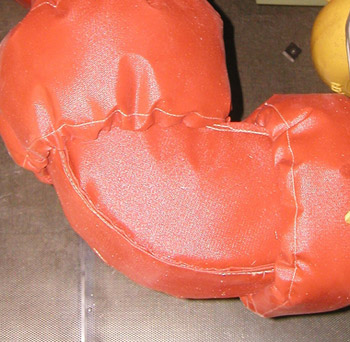

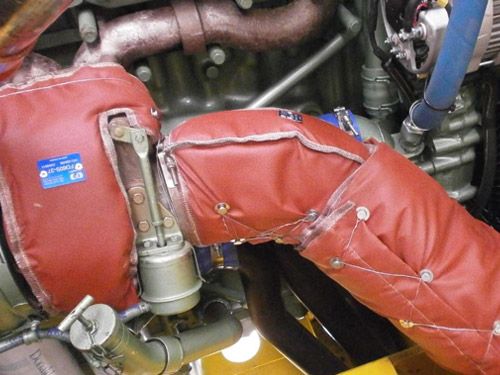

Next to straight pipes and tubes, the most common component to get wrapped with removable insulation blankets is the elbow. In order to manufacture a custom blanket for a particular elbow, there is some basic information that Firwin would need to know.

90° Elbows :

90° Elbows are probably the most common of all the elbows. All that is needed here is the pipe diameter, radius and the length of any extensions. If the 90° is a standard short radius (radius = diameter) or long radius (radius = 1.5*diameter), then the only measurements needed would be the pipe diameter and the length of any extensions.

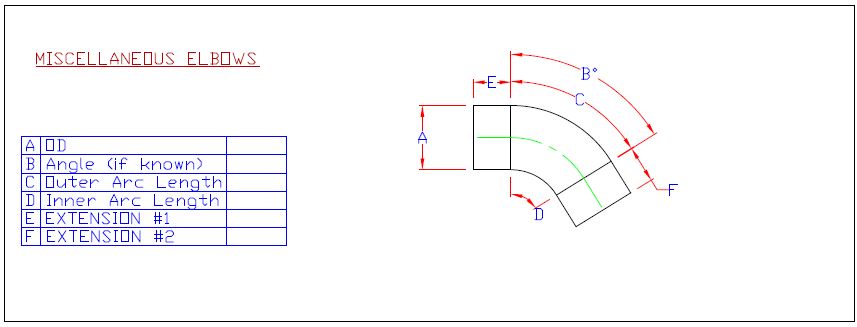

Non 90° Elbows :

For non 90° Elbows, in addition to the pipe diameter, radius, and extensions, the elbow angle would be required.

If measuring the angle & radius of a non-standard elbow is difficult to do, as can sometimes be the case, the ‘arc method’ below is a good alternative :

Measuring Elbow Arcs:

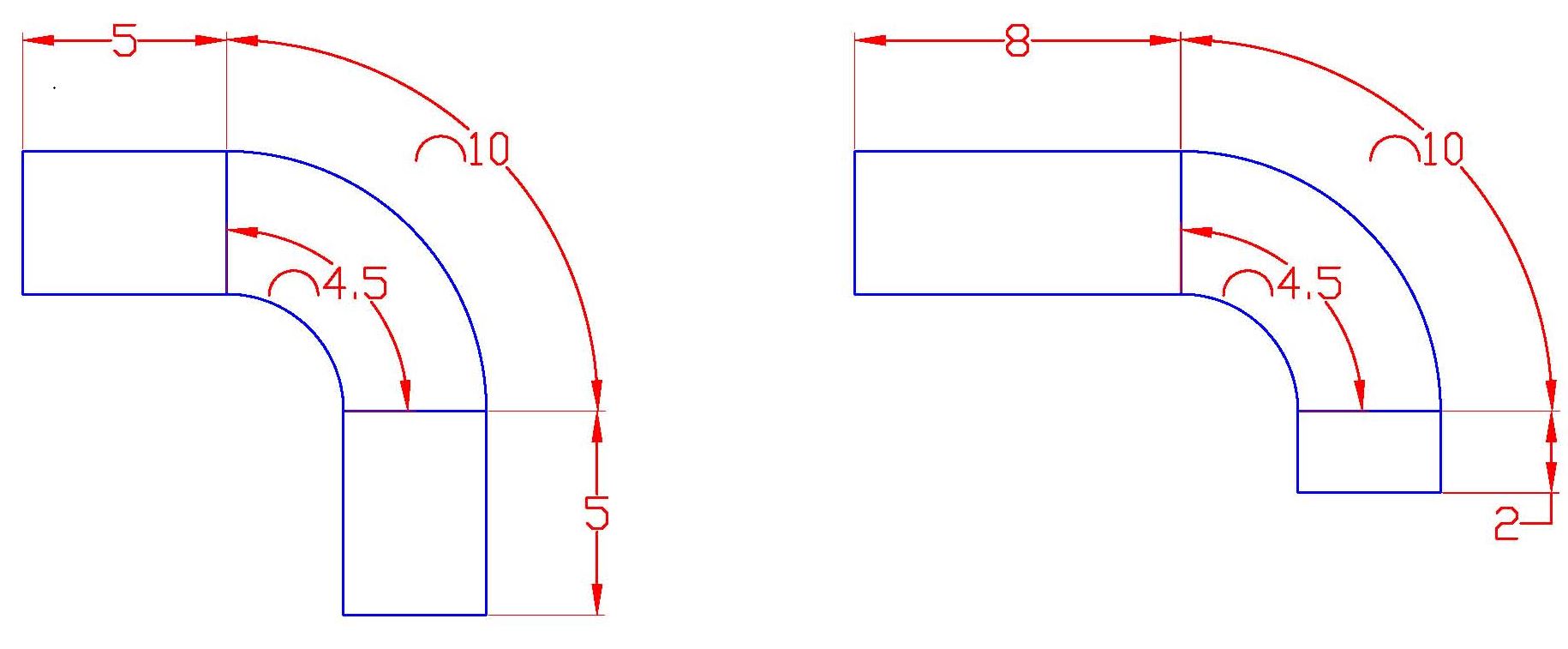

An alternative to measuring the radius & angle is to measure the lengths of the elbow inner and outer arc. When doing this, it is important to still separate any extensions and not include them in the arc measurements. Firwin’s blanket designers need to know where the elbow ends and the extensions begin. This is because an overall arc length (one that includes the elbow and the extensions) can represent more than 1 elbow configuration, even for an identical elbow, as can be seen the example below. (Both elbows have an outer arc length of 20; without knowing the extensions, a properly fitting blanket can not be designed).

Mitered Elbows:

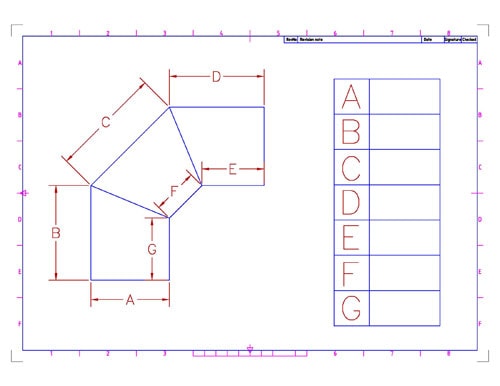

Also known as ‘segmented elbows’, mitered elbows require a slightly different measurement. Asides from the pipe diameter, the lengths of the outer & inner edges are needed.

Threaded Elbows :

Threaded Elbows typically follow a standard configuration. So by notifying Firwin that the elbow is threaded and what the pipe size is, our designers can build the blanket accordingly.