Locomotive engines operate at extremely high temperatures within a confined area, which can result in a dangerous environment for workers and equipment alike. With the limited space available on trains, it is easy for workers to come into contact with extremely hot engine and exhaust components. Such exposure can result in severe burns, heat exhaustion, and other health hazards. In addition to health risks, overheated exhaust systems can allow heat to rise above safe levels, leading to equipment damage and heightened fire risk.

Firwin is pleased to offer insulation blanket solutions for locomotive engines and exhaust equipment to help control, disperse, and redirect excess heat. Our removable insulation blankets offer easy access to engine components and exhaust systems for maintenance and can be customized to fit around unusual configurations and protruding pipes and fixtures, ensuring optimal coverage and protection.

Firwin's Removable Blanket Materials and Construction

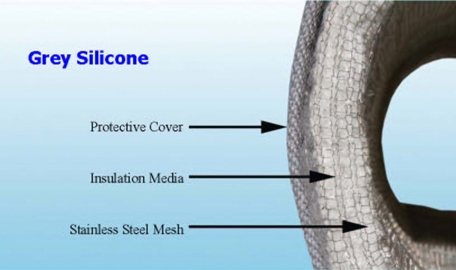

Removable insulation blankets typically consist of three layers:

Removable insulation blankets typically consist of three layers:

- The outer layer is a protective cover composed of silicone-impregnated or aluminized fiberglass. Depending on the material, the outer cover can withstand temperatures up to 500 ºF (260 ºC) and 600 ºF (316 ºC). Aluminized fiberglass fabric can handle temperatures as high as 1000 ºF (538 ºC).

- The middle layer of a removable insulation blanket generally consists of a fiberglass or CMS wool filler approximately 1″ thick. These materials are capable of withstanding 1200 ºF (649 ºC) for fiberglass, and 2000 ºF (1093 ºC) for CMS wool.

- The inner layer consists of a steel mesh or fibrous material that can withstand temperatures up to 2000 ºF (1093 ºC). Since this is the layer that is closest to the heat source, the inner layer must be extremely durable and heat-resistant.

For applications with unusual or particularly demanding parameters, Firwin is pleased to offer a broad range of alternative materials and blanket designs. All of our removable blankets can be tailored to meet the specific needs of your application.

Locomotive Safety and Efficiency With Firwin Insulation

Adequate insulation for locomotive engine and exhaust components is critical for safe and effective equipment operation. Insulation protects workers from burns and excessive ambient heat when they must work in close proximity to exhaust and engine components. In addition, appropriate insulation helps to reduce engine room noise, further improving working conditions.

Adequate insulation for locomotive engine and exhaust components is critical for safe and effective equipment operation. Insulation protects workers from burns and excessive ambient heat when they must work in close proximity to exhaust and engine components. In addition, appropriate insulation helps to reduce engine room noise, further improving working conditions.

Functionally, insulation blankets help to reduce heat loss within the system, providing more effective SCR and catalyst operations. Well-fitted insulation blankets also keep heat contained to specific equipment, thereby reducing the risk of damage to nearby heat-sensitive components and instruments.

Firwin’s removable blanket insulation features quick-release fastening for fast installation on HEP and drive engines. The easy-to-use design offers easy access and quick turnarounds on maintenance, inspection, and repair visits. Easy access means more frequent, better quality inspections and service, which will ensure that equipment is in optimal working condition to reduce the need for expensive repairs and equipment replacement down the road.

Insulation of locomotive exhaust and engine components is necessary for both worker safety and equipment functionality. Firwin has been a leading manufacturer of top quality insulation solutions for a broad range of industries and applications, from industrial applications to power generation facilities. As an ISO 9001-certified manufacturer, our products are made to meet and exceed some of the most rigorous industry standards.