Heat is a common byproduct of various industrial and automotive applications. Without proper shielding, heat can pose numerous hazards for workers and nearby equipment. Heat shields are specialized materials designed to prevent heat from entering the surrounding area. At Firwin, we offer a range of removable heat shielding products capable of protecting equipment and personnel from high levels of heat. Regardless of your industry or application, our experts can work with you to determine the ideal heat shield solution.

Firwin’s Custom Heat Shield Products

Firwin is a top provider of high-quality heat shielding and insulation products, including:

Hard Coat™ Insulation: This type of durable heat shielding is constructed with a heat-resistant composite material. It features a hard exterior while remaining lightweight and conforms tightly to the part, making it ideal for limited-space applications.

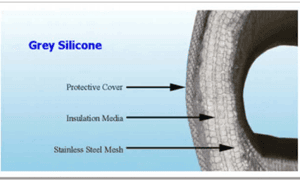

Removable Insulation Blankets: These removable heat shields are used to insulate engine parts, exhaust pipes, and industrial process equipment and piping. They are available in various thicknesses and insulation media to offer varying degrees of heat reduction.

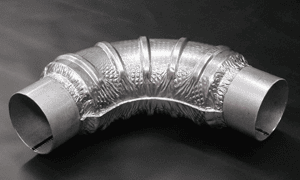

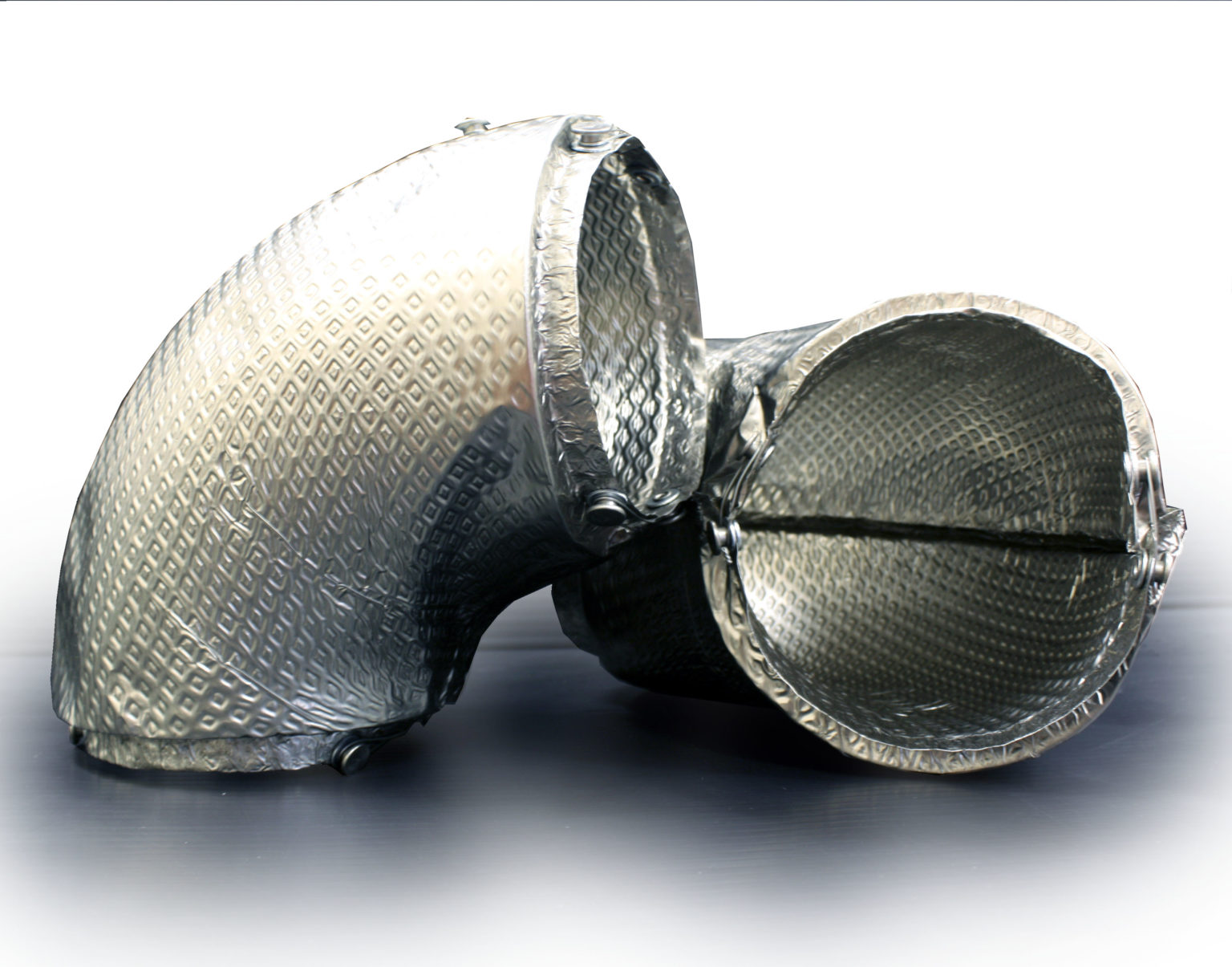

Metal Foil Insulation (MFI™): Our MFI Metal Foil Insulation products can be designed to contour to complex shapes, with customizable thicknesses and insulation materials to match your unique application. They are particularly suitable for use on exhaust system components, such as piping, tubing, elbows, and more.

Common Industries Served

At Firwin Corporation, we’re committed to providing our customers with top-quality custom heat shielding products for gas engines, diesel engines, exhaust systems, and various industrial applications.

Some of the specific industries we serve include:

- Aerospace

- Automotive

- Marine

- Oil & Gas

- Underground Mining

Heat Shield Benefits

Heat shields from Firwin offer a wide range of benefits, including:

- Reduced heat transfer. One of the main benefits of heat shielding is its ability to protect surrounding environments from hazardous heat generated by equipment.

- Increased employee safety. Heat shields reduce heat exposure for workers and prevent nearby equipment from overheating.

- Improved thermal management. Custom heat shields help to maintain optimal operating temperatures for more efficient equipment performance.

- Longer lifespan for equipment. Heat shields can protect equipment from heat-related damage, resulting in improved longevity.

- Reduced energy consumption. Depending on the specific application, heat shielding can optimize energy efficiency for enhanced sustainability and lower costs.

Heat Transfer Types

Heat shields can effectively insulate equipment in a variety of applications. The type of heat shield you use depends largely on the way the heat is being transmitted. There are three typical types of heat transference that can be treated using heat shields.

Conductive heat

Heat transmitted between objects through direct contact.

Radiant Heat

Heat is generated from a solid source and radiates outward to indirectly affect objects in the surrounding area

Convective Heat

Transmitted between solid objects and the movement of fluid or gas objects through direct contact.

To ensure you have the correct barrier for your application, it is important to consider the way the heat travels through and away from your equipment. The most common heat treatments are dissipators, reflectors, and insulators. Each method uses a different operating principle to mitigate heat loss, and they can be used in conjunction to produce results tailored to the needs of specific applications.

Partner With Firwin: Your Source for Customized Heat Shield Solutions

Looking for reliable heat shield insulation products for your application? Firwin Corporation has what you need to increase your equipment efficiency, improve safety for personnel and equipment, and prevent potentially costly heat damage. As an ISO 9001:2015 and UL2200 certified company, Firwin is dedicated to providing high-quality heat shield solutions that meet your unique needs.

Have more questions about our products? Contact us today, and we’ll connect you with one of our experts. You can also request a quote to start your next project with us.

Featured Resources

Gain more insight into insulation blankets with three of our most popular eBooks.

Choosing the Right Insulation Blanket Supplier

Download

Tapes & Sleeves vs. Removable Covers

Download