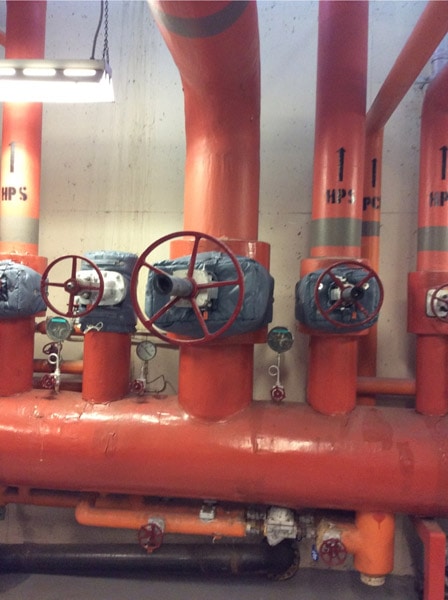

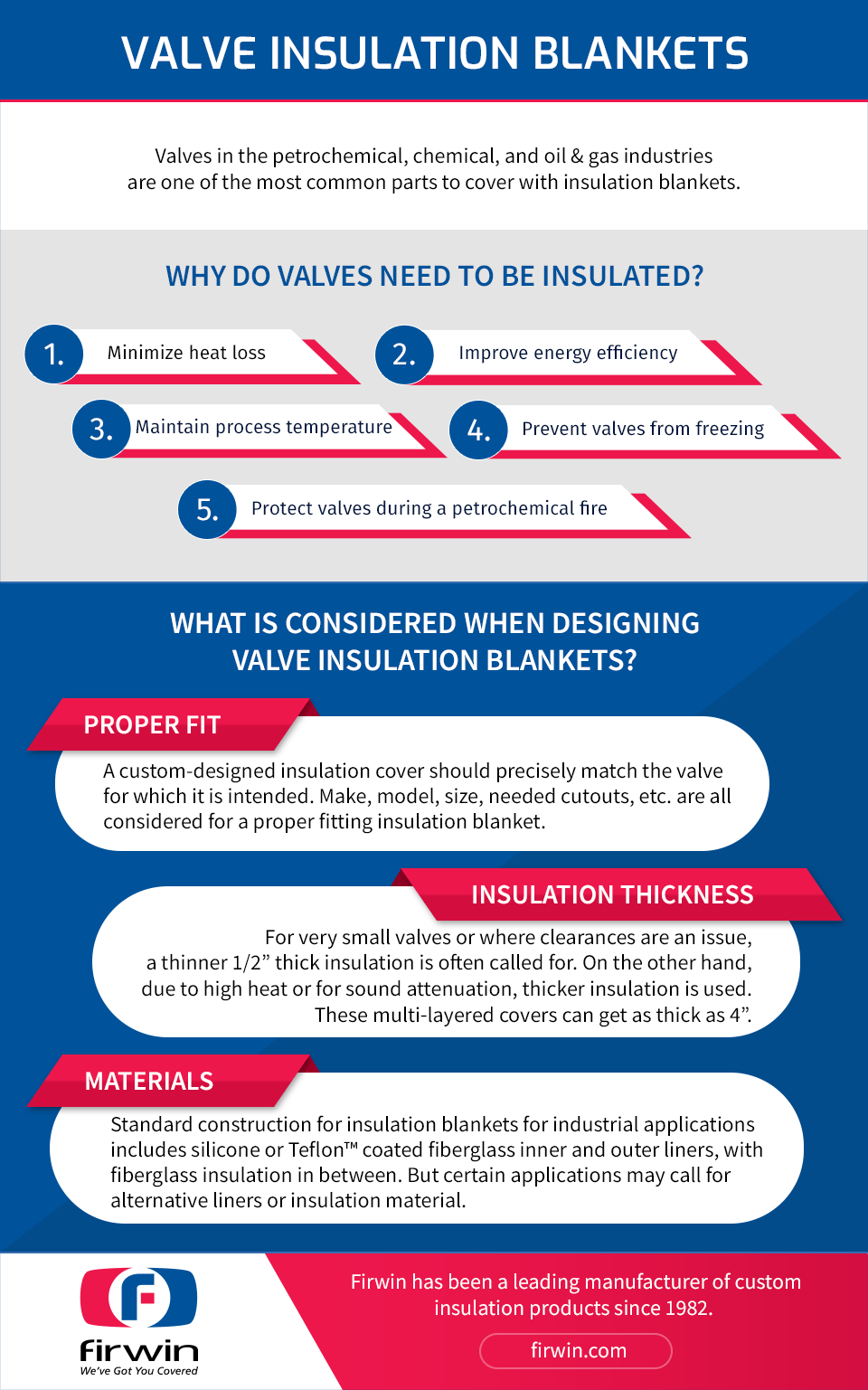

Valves are one of the most common parts to cover in the petrochemical, chemical, and oil and gas industries. Like process line piping, valves often need to be insulated to minimize heat loss for energy efficiency or to keep the contents of the materials flowing through the valve at a desired temperature. In addition, insulation blankets keep the valve parts from freezing up in cold temperature operations. However, unlike process line piping, which is often insulated with permanent insulation or cladding, valves generally must be kept accessible to maintenance personnel in case they need servicing or are required during an emergency situation. This makes valves ideal candidates for removable / reusable insulation covers.

Removable Valve Covers – What to Look For?

When dealing with removable insulation covers, one size does not fill all. Here are some variables that Firwin’s design team considers when designing removable insulation covers:

Proper fit: Valves can come in a variety of configurations—gate valves, flow valves, butterfly valves, etc.—with a large variety of makes, models, and sizes within each category. Each of these has their own unique geometry, and a custom designed insulation cover should precisely match the part for which it is intended. Valve orientation or presence of adjacent valves or piping can also affect the final blanket design. In cold weather climates, valves are also subject to glycol, water, steam, or electric heat tracing. Properly positioned cut-outs are essential for an insulation cover to fit properly and function as intended.

Insulation thickness: While removable insulation covers typically contain a 1” thick insulation material, this thickness can vary depending on the needs of the particular application. For very small valves or where clearances are an issue, a thinner 1/2” thick insulation is often called for. On the other hand, there are instances where a thicker insulation is needed due to high heat or for sound attenuation. In addition to requiring a thicker insulation, sound attenuation needs a multi‐layered construction, with an additional layer of sound dampening material. These multi‐layered covers can get as thick as 4”.

Materials: Standard construction for removable insulation covers for industrial applications include silicone or Teflon™ coated fiberglass inner and outer liners, with a fiberglass insulation in between. But certain applications may call for alternative liners or insulation material. For instance, where temperatures higher than 500°F are present, silicone/Teflon inner liners will not suffice, and a higher temperature alternative, such as Firwin HT, is necessary.

Removable Insulation Covers From Firwin

Since 1982, Firwin has been a leading manufacturer of custom insulation products for piping, valves, engines, and an expansive range of other industrial purposes. Our main product lines include permanent Hard Coat™ composite insulation and removable insulation blankets. Since our inception, we have been offering safe and effective insulation solutions for a variety of industries.

Along with offering top quality insulation products, we are also committed to providing exceptional customer service through sales, installation, and product selection. To learn more about Firwin’s products or to get started on a project with our team, contact us today.

Comments are closed