Industrial equipment is prone to producing high heat levels when in operation, which can impact the surrounding areas. This can lead to uncomfortable, or even dangerous, working environments for personnel, and it can negatively impact the performance of surrounding machinery. Heat shields are used to reduce the effect of high temperatures in areas around equipment that generate heat. They are specifically designed to protect equipment and personnel from high heat levels. There are several types of heat shields available, and selecting the right heat shield for your application depends on several factors, including the end-use, the surrounding environment, and the industry.

What is a Heat Shield?

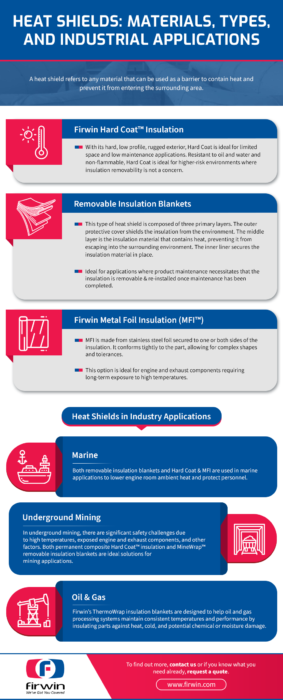

A heat shield refers to any material that can be used as an obstacle to prevent heat from entering the surrounding area. A heat shield can be removable, like an insulation blanket, to allow for easy service access, or it can be permanent, like a hard coating material that is used to insulate surrounding components.

Some of the most common heat shield types include:

- Firwin Hard Coat™ Insulation: Hard Coat™ is a composite material composed of ceramic fiber insulation with a high alumina content. This is covered by a heat-resistant and highly durable composite. Hard Coat™ insulation forms a permanent, hard, and rugged exterior, making it ideal for applications with low maintenance requirements. Hard Coat™ insulation is non-flammable and resistant to water and oil, making it ideal for applications that are exposed to high temperatures for long periods.

- Removable Insulation Blankets: This type of heat shield is composed of three primary layers. The outer protective cover shields the insulation from the environment. The insulation mat is composed of insulation material and contains heat, preventing it from escaping into the surrounding environment. The inner liner secures the insulation blanket in place. Removable insulation blankets can be reused and are ideal for equipment that requires periodic maintenance. Insulation blankets can also be constructed to act as shields for preventing fluids from reaching exhaust and engine components.

- Firwin Metal Foil Insulation (MFI™): MFI™ is made of either aluminized polyester or aluminum foil that is secured to one or both sides of the heat shield. The foil reflects the heat, preventing it from escaping the insulation. This option is ideal for exhaust system components, such as elbows, tubing, and piping, that require pre-installed insulation. It acts as a barrier to fluid seepage. MFI™ offers superior durability, which means that it can withstand steam solvent/washing.

Heat shields mitigate heat damage to sensitive components and can protect against burns. They also allow equipment that requires high operating temperatures to run optimally while protecting the surrounding environment.

Heat Shields in Industry Applications

Heat shields are beneficial in a wide range of applications. Different industries utilize different types of heat shields to fit the needs of their application and the surrounding environment. Some of the most common heat shield applications include:

Marine

The tight quarters and constant engine operation in marine applications can quickly create a dangerous environment for those on board. With such limited space, the chances of personnel getting injured from an overheated component raise exponentially. Both removable insulation blankets and permanent hard coat insulation are ideal for different components in marine applications to facilitate safe heat control through dispersion and redirection.

Underground Mining

In underground mining, there are significant safety challenges due to high temperatures, exposed engine and exhaust components, and other factors. Both permanent composite Hard Coat™ insulation and MineWrap™ removable insulation blankets are ideal solutions for mining applications. The permanent solution coats equipment in a thin insulation layer that prevents oil and hydraulic fluid from engine leaks or broken hoses from building up on or igniting equipment; while MineWrap™ removable blankets have a mesh reinforced foil interior that shields the insulation material. Both solutions cover the exposed exhaust and engine components, reducing heat and improving the shielding of workers from burns.

Oil & Gas

The oil and gas industry also faces similar safety challenges, however, heat retention is critical to the optimal functioning of process systems. Firwin’s ThermoWrap™ insulation blankets are designed to contain heat to the oil and gas, petrochemical, and industrial components to improve efficiency and protect employees. Each blanket is custom manufactured to wrap around the component needing insulation.

Why choose Firwin?

Firwin offers heat shields that protect employees from physical harm, prevent flammable fluid ignition, mitigate heat damage in the surrounding environment, and lower temperatures. Firwin is a leading manufacturer of insulation products for diverse industrial applications. To find out more, contact us or if you know what you need already, request a quote.

Comments are closed