Exhaust pipe heat shields are integral to safe, efficient machine operations and maximizing equipment’s longevity. However, it’s important to choose the right heat shield exhaust pipe insulation for your equipment to best protect your exhaust system and secure the optimal benefits for your workers and facility. At Firwin Corporation, we offer custom, high-performance exhaust pipe insulation solutions for diverse applications.

Importance & Benefits of Exhaust Pipe Insulation

High-heat machinery must maintain specific operating temperatures based on its applications to function as intended. Doing so also means managing internally generated heat to protect such machines from degradation. Exhaust pipes serve to safely and effectively release that heat or steam from a system. Improper exhaust can otherwise lead to hazardous buildup or other issues that are costly to repair.

Heat shields provide insulation for the exhaust pipes and tubes, ensuring peak equipment performance, elongating machinery’s life cycles, and helping to keep workers from making direct contact with hot surfaces. Ideally, these thermal barriers should be capable of:

- Expanding and contracting with exhaust piping

- Withstanding constant vibration

- Fitting around unique configurations and mounting components

- Allowing accessibility for future system maintenance and repairs

Best Heat Shield Types for Exhaust Pipe Insulation

Firwin specializes in several innovative, customizable exhaust pipe insulation solutions for maintaining proper operating temperatures, protecting staff and surrounding equipment, and optimizing machine functionality.

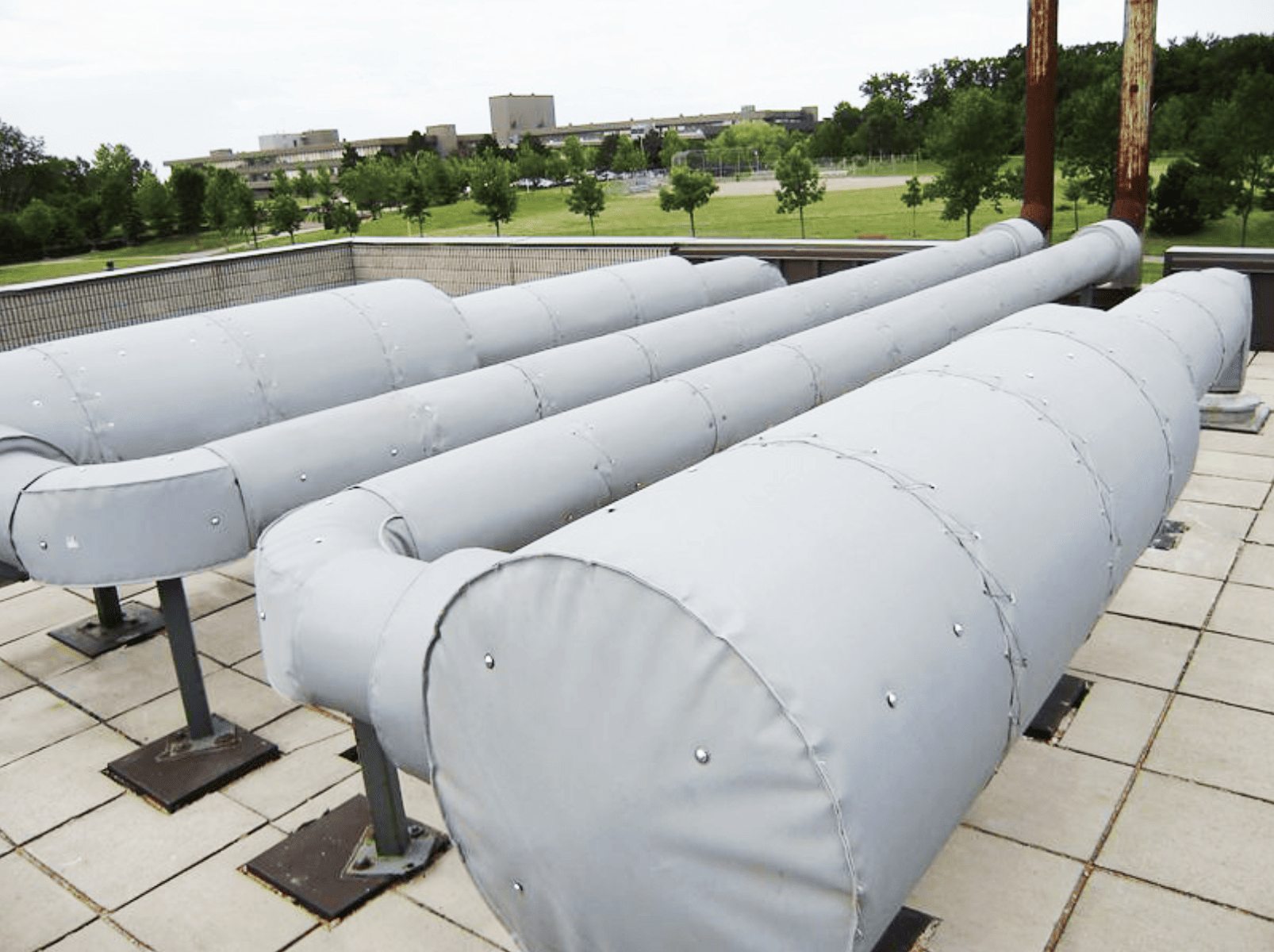

Removable Insulation Blankets

Our UL2200-certified removable insulation blankets accommodate exhaust pipes and elbows while allowing for clamps, brackets, hangers, flanges, bellows, expansion joints, flex connectors, and more. These fully reusable heat shield solutions are ideal for machinery that necessitates frequent maintenance as they’re simple to remove and replace.

We carefully match our materials and designs to your system requirements, including temperature thresholds, expansion/contraction needs, vibration, and more. Firwin’s removable insulation blankets are available with 1200° F and 2100° F maximum heat limits for the insulation media, with a three-layer construction that consists of:

- An outer protective cover typically made of silicone-impregnated or aluminized fiberglass that safeguards the insulation against its environment

- An insulation mat of fiberglass or CMS wool media (other materials are available) that prevents heat from escaping into the environment

- An inner liner made up of stainless steel mesh or a high-temperature material that holds the blanket in place

We also offer a range of alternatives for both construction and materials, as needed, to best suit your needs.

T-Wrap™

Firwin’s T-Wrap™ combines the advantages of removable insulation blankets with the flexibility of tape. It’s an ideal insulation solution for smaller tubes, pipes, and valves, as well as instrumentation, glycol, and electrically traced lines. T-Wrap features:

- An outer cover of silicone-coated fiberglass

- A 0.25- or 0.50-inch fiberglass insulation layer

- Hook and loop strips on the sides for simplified fastening and removal

Available in cuttable 20-foot lengths, T-Wrap comes in widths of 4 inches to 17 inches. Its standard service temperature range is -67° F to 200° F. However, as with our removable insulation blankets, we can custom-design our T-Wrap product to handle higher temperature limits.

Metal Foil Insulation (MFI)

Featuring pre-installation with an exterior foil cover that’s joined to a component with a permanent weld, or available in a removable configuration (similar to our blankets), our MFI product is both highly functional and aesthetically pleasing. This durable insulation solution and fluid barrier comes in customizable thicknesses and various material options to best address your unique needs. MFI is an optimal choice for pipes, tubes, elbows, and related exhaust system parts in complex shapes, as well as OEMs requiring low or average quantities. The cover and the insulation media it encapsulates can maintain their integrity even under exposure to solvents or steam washing.

Permanent HC Hard Coat™ Composite Insulation

Distinctive for its permanent application, our Hard Coat™ insulation consists of a high-alumina ceramic fiber with a high-temperature, durable outer coating. The insulation can support a maximum temperature of 2192° F but typically operates at 1200° F or below. Available in 0.5- and 1.0-inch thicknesses, it’s rated for continuous use at 1300° F and 1800° F, respectively. Hard Coat is long-lasting, oil- and moisture-resistant, and non-flammable, meeting FAR part 25.853 self-extinguishing standards. Because Hard Coat adheres permanently to structures or components, it’s not recommended for exhaust parts requiring direct-contact servicing.

Contact the Experts at Firwin for Premium Exhaust Pipe Insulation Solutions

Specializing in custom-manufactured insulation solutions for exhaust systems as well as gas and diesel engines, Firwin offers both removable and permanent heat shield products for varied industries. Backed by over 40 years of experience, an in-house design team, and an ISO 9001:2015-certified quality management system, Firwin provides an innovative line of cost-effective products that we can tailor to your exact specifications.

Contact us to ask our experienced insulation specialists about your exhaust pipe heat shielding needs, or request a quote today to get started.

Comments are closed