The performance of an insulation material is primarily determined by its ability to reduce the exchange of heat energy from a surface to the environment or between two surfaces. An insulation’s ability to insulate is typically determined by its thermal conductivity, operating conditions, and material thickness.

This blog will explore how to rate the performance of industrial thermal insulation. We will discuss how K, U, R, and C-value ratings apply to an insulation material’s performance and help you determine the optimal insulation product for your application.

Rating the Performance of Industrial Thermal Insulation

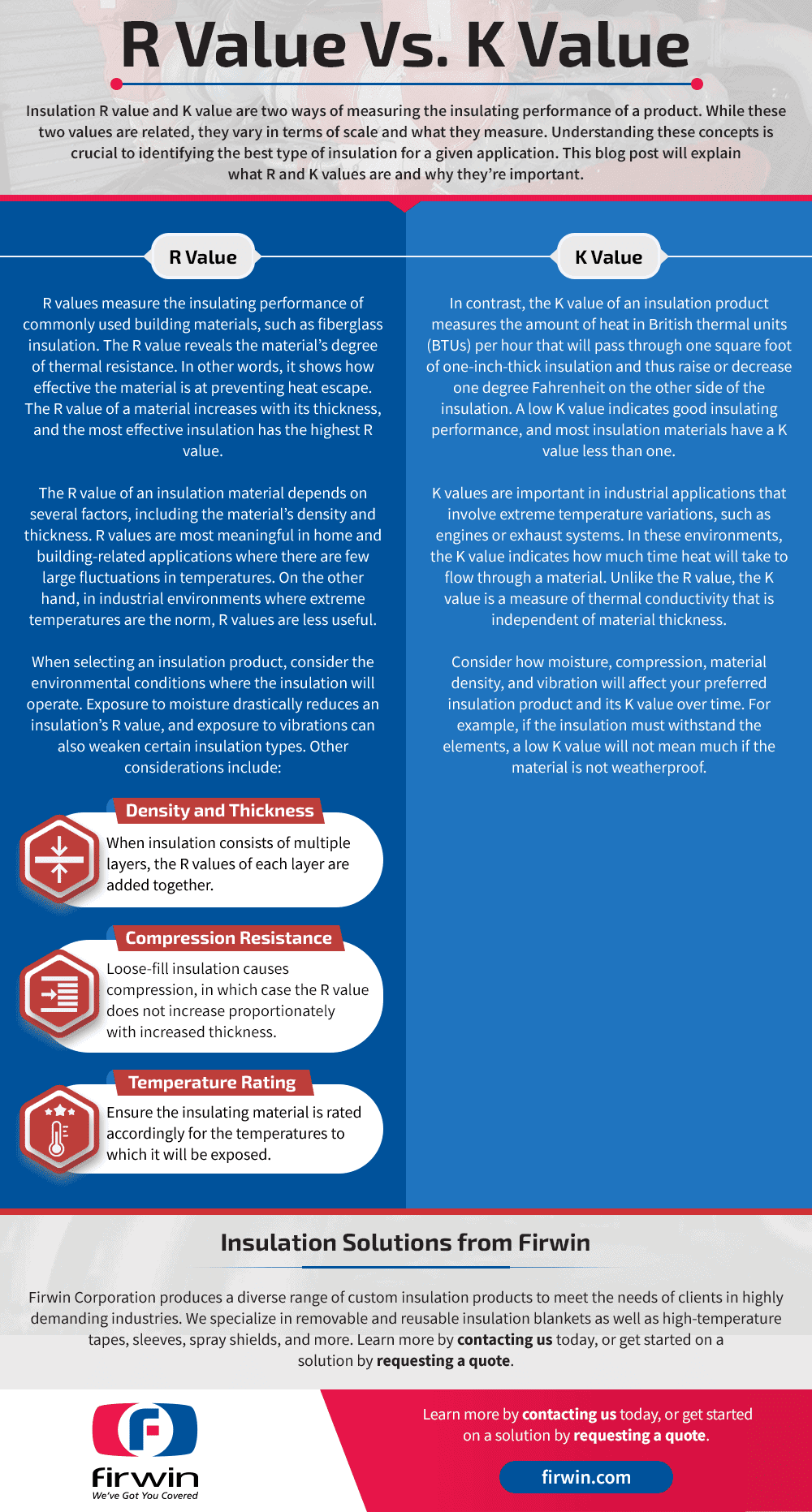

Thermal insulation’s primary purpose is reducing the exchange of heat between two distinct environments. When you are selecting an insulation for your application, K, U, R, and C-value ratings are crucial considerations, each representing a factor in thermal insulation performance. The values are determined by the type of material and can be affected by its thickness. Here’s what each value means:

- K-Value: This represents a material’s thermal conductivity, measuring its ability to conduct heat energy. A low K-value insulation delivers good insulation performance, and most insulation products have a K-value lower than 1. Specifically, the K-value measures the heat in BTUs (British thermal units) per hour that passes through one square foot of one-inch-thick insulation, thus decreasing or increasing the temperature by 1 °F on the other side of the material. K-value is important in applications with extreme temperature differences, such as exhaust systems and engines.

- R-Value: R-value is a material’s thermal resistance, describing its effectiveness at preventing heat escape. An insulation’s R-value increases with its thickness and density, so the higher the R-value, the better the insulation. R-value calculations are most useful in residential or building applications, where there are few large temperature fluctuations.

- U-Value: Also known as thermal transmittance, U-value refers to the rate of heat transfer through a material. A low U-value insulation transmits thermal energy more slowly, providing better insulation properties.

- C-Value: A measurement of conductivity similar to the K-value, the C-value is the thermal conductance factor measuring the amount of heat that passes through one foot of the insulation material. The lower the C-value, the better the insulation performance.

In Summary

If you are looking for the ideal insulation for your facility, here are some key takeaways:

- A low U-value delivers better insulation to a system. The ideal insulation for a given application will often have a low U-value.

- Insulation materials with a higher R-value and lower C-value provide improved insulating performance.

- If a particular material has a low K-value, it offers good insulation for that material’s thickness and a given set of operating conditions.

Facility managers depend on these properties to give them the information they need to select the thermal insulation materials that will optimize energy savings, worker protection, process control, and condensation control.

Contact Firwin for Your Industrial Insulation Needs

When selecting thermal insulation, it is critical to understand U, R, C, and K-value ratings to determine the type of insulation your application requires. It is also essential to consider the insulation’s installation environment and operating conditions like moisture, compression, temperature, and other factors that could affect insulation performance.

Firwin Corporation produces various custom insulation solutions to meet the requirements of our clients and their highly challenging applications. Our team can provide you with expert guidance on choosing the right thermal insulation product based on its K, U, R, and C-values, matching it to your specific application. Firwin offers reusable and removable insulation blankets, spray shields, sleeves, high-temperature tapes, and more.

Contact us or request a quote to speak with an insulation specialist about the ideal solution for your application.

Comments are closed