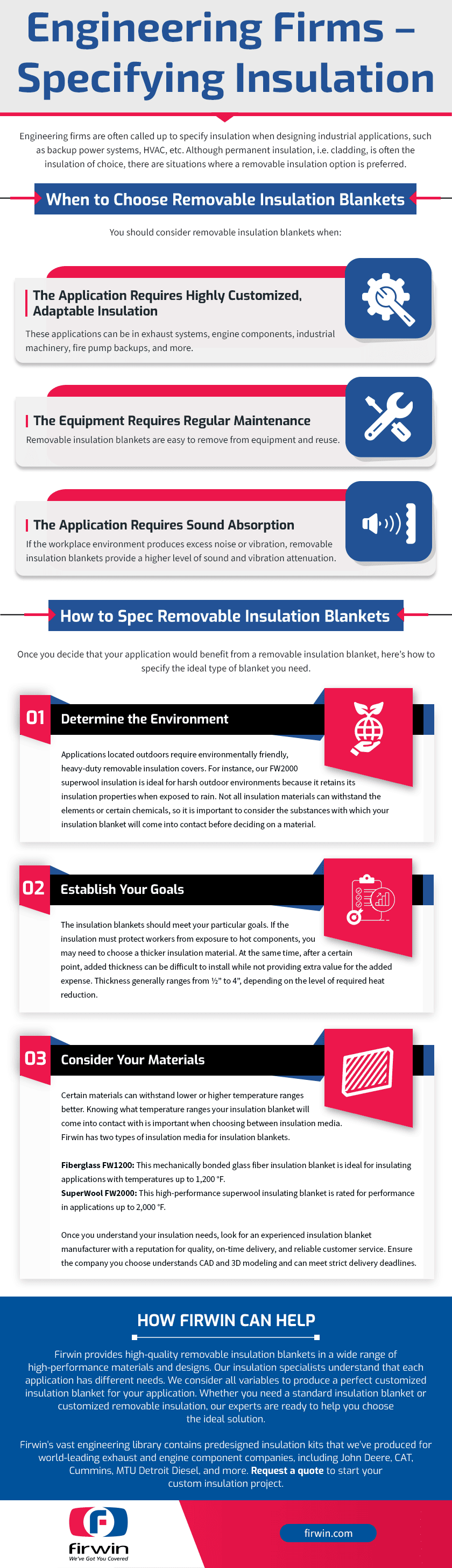

Engineering firms are often called up to specify insulation when designing industrial applications, such as backup power systems, HVAC, etc. Although permanent insulation, i.e. cladding, is often the insulation of choice, there are situations where a removable insulation option is preferred.

When to Choose Removable Insulation Blankets

You should consider removable insulation blankets when:

- The application requires highly customized, adaptable insulation. These applications can be in exhaust systems, engine components, industrial machinery, fire pump backups, and more.

- The equipment requires regular maintenance. Removable insulation blankets are easy to remove from equipment and reuse.

- The application requires sound absorption. If the workplace environment produces excess noise or vibration, removable insulation blankets provide a higher level of sound and vibration attenuation than permanent hard coat insulation.

How to Spec Removable Insulation Blankets

Once you decide that your application would benefit from a removable insulation blanket, here’s how to specify the ideal type of blanket you need.

Determine the Environment

Applications located outdoors require environmentally friendly, heavy-duty removable insulation covers. For instance, our FW2000 superwool insulation is ideal for harsh outdoor environments because it retains its insulation properties when exposed to rain. Not all insulation materials can withstand the elements or certain chemicals, so it is important to consider the substances with which your insulation blanket will come into contact before deciding on a material.

Establish Your Goals

The insulation blankets should meet your particular goals. If the insulation must protect workers from exposure to hot components, you may need to choose a thicker insulation material. At the same time, after a certain point, added thickness can be difficult to install while not providing extra value for the added expense. Thickness generally ranges from ½” to 4”, depending on the level of required heat reduction.

If you need to protect crucial components from chemical fires, you’ll need a specialized insulation material, like Firwin’s fire blankets. Whatever your objectives are, make sure the insulation manufacturer you’re working with understands your goals and how to achieve them in the most efficient way possible.

Consider Your Materials

Certain materials can withstand lower or higher temperature ranges better. Knowing what temperature ranges your insulation blanket will come into contact with is important when choosing between insulation media. Firwin has two types of insulation media for insulation blankets.

- Fiberglass FW1200: This mechanically bonded glass fiber insulation blanket is ideal for insulating applications with temperatures up to 1,200 °F.

- SuperWool FW2000: This high-performance superwool insulating blanket is rated for performance in applications up to 2,000 °F.

Once you understand your insulation needs, look for an experienced insulation blanket manufacturer with a reputation for quality, on-time delivery, and reliable customer service. Ensure the company you choose understands CAD and 3D modeling and can meet strict delivery deadlines.

How Firwin Can Help

Firwin provides high-quality removable insulation blankets in a wide range of high-performance materials and designs. Our insulation specialists understand that each application has different needs. We consider all variables to produce a perfect customized insulation blanket for your application. Whether you need a standard insulation blanket or customized removable insulation, our experts are ready to help you choose the ideal solution.

Firwin’s vast engineering library contains predesigned insulation kits that we’ve produced for world-leading exhaust and engine component companies, including John Deere, CAT, Cummins, MTU Detroit Diesel, and more. Request a quote to start your custom insulation project.